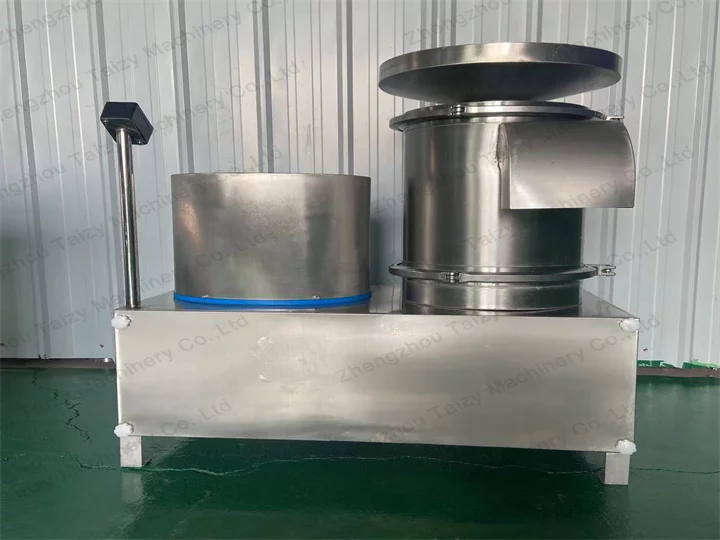

La máquina comercial para romper huevos, a menudo denominada aldaba de huevos, es un equipo especializado diseñado para separar las cáscaras de huevo del líquido del huevo mediante un diseño centrífugo. Sólo 1% del líquido del huevo permanece en la cáscara del huevo, lo que mejora en gran medida la tasa de recolección del líquido del huevo. Con su diseño centralizado, gran capacidad y tamaño reducido, la máquina trituradora de huevos comercial se puede aplicar fácilmente a pequeñas y medianas empresas procesadoras de alimentos.

Diversas características de la máquina para romper huevos

- Alta capacidad de producción. El rompecáscaras de huevo puede procesar huevos 600-800 kg/h, alta eficiencia de producción y ahorro de costes laborales.

- Alta tasa de extracción de líquido de huevo. La red de descarga adopta una estructura de tamiz cosido con alta resistencia mecánica, que no es fácil de dañar ni obstruir. La filtración del líquido del huevo es mejor, sin impurezas granulares.

- Fácil de operar. El operador sólo necesita colocar los huevos limpios en el puerto de alimentación.

- Higiénico y seguro. La máquina rompehuevos está hecha de 304 Acero inoxidable, de fácil limpieza y mantenimiento para garantizar la higiene de los alimentos.

- Las cáscaras de huevo son fáciles de reciclar. A medida que se rompe la cáscara del huevo, la máquina trituradora de huevos comercial reduce el volumen y logra una reducción de las emisiones.

- Huella pequeña. Pequeño volumen, fácil de mover. La trituradora de huevos tiene un bajo costo de inversión y se puede utilizar sin un gran taller.

Proceso de trabajo del batidor de huevos automático

Fase de preparación: limpiar los huevos, eliminar las impurezas de la superficie para garantizar la higiene de las materias primas.

Alimentación: colocar los huevos limpios en el rompedor de huevos a través del puerto de alimentación.

Proceso de separación: después de arrancar la máquina, los huevos se romperán automáticamente bajo el efecto centrífugo producido por la rotación a alta velocidad. Y el líquido de huevo y la cáscara de huevo se separarán.

Descarga: las cáscaras de huevo son elevadas por la jaula del cabrestante y descargadas por el puerto de residuos. El líquido de huevo limpio final se recoge para su posterior procesamiento.

Limpieza y mantenimiento: después de completar el trabajo, la máquina comercial rompedora de huevos debe limpiarse y mantenerse para garantizar la higiene y el rendimiento para el próximo uso.

¿Para qué aplicaciones se puede utilizar la máquina batidora de huevos?

El rompedor de huevos se puede aplicar en cafeterías, pastelerías, panaderías, tiendas de comida occidental, tiendas de bebidas, fábricas de producción de comida rápida informal y otros lugares donde se necesiten procesar huevos de manera eficiente.

Máquina comercial para romper huevos a la venta

| Voltaje | 380 V, trifásico |

| Fuerza | 3 kilovatios |

| Capacidad de procesamiento | 600-800kg/hora |

| Tamaño de apariencia | 950*75*1100 milímetros |

| Peso | 150 kilogramos |

Además del modelo, también podemos personalizar la máquina rompehuevos automática según su capacidad de tratamiento y demanda.

Somos un fabricante con 13 años de experiencia en el desarrollo de maquinaria alimentaria. Para equipos relacionados con huevos, también tenemos lavadoras de huevos, clasificadoras de huevos, máquinas separadoras de clara y yema de huevo y así sucesivamente. Bienvenido a consultarnos para obtener más información sobre el precio, la configuración y los parámetros de la máquina rompedora de huevos.

¿Cómo elegir fabricantes de máquinas para romper huevos de alta calidad?

Brinde más oportunidades a proveedores de equipos alimentarios con experiencia y reputación. No solo pueden garantizar la calidad de las máquinas batidoras de huevos, sino que también brindan un excelente servicio posventa.

Además de evaluar proveedores, puede comparar los precios de los equipos de varios proveedores. Las empresas pueden controlar el costo de inversión y lograr un desarrollo sostenible al tiempo que garantizan la eficiencia de la producción.

Métodos de mantenimiento de la máquina automática para romper huevos

Limpieza periódica

Después de cada uso, limpie el interior y el exterior del equipo de manera oportuna para evitar el crecimiento de bacterias debido a los residuos del líquido del huevo. Y utilice agua tibia y agentes de limpieza adecuados, evite el uso de agentes de limpieza corrosivos para dejar de dañar los materiales del equipo.

Mantenimiento de lubricación

Lubrique periódicamente las piezas móviles para garantizar un funcionamiento mecánico suave y reducir el desgaste.

Comprobar sujetadores

Revise periódicamente los sujetadores de la máquina comercial para romper huevos para asegurarse de que no estén flojos. Es necesario comprobar especialmente las piezas con grandes vibraciones. Si encuentra holgura, apriételas a tiempo para evitar fallas o accidentes.

Verificar el sistema eléctrico

Realice comprobaciones periódicas del cable de alimentación para garantizar un buen aislamiento y evitar fugas.

Preguntas frecuentes

¿Qué debo hacer si el golpeador de huevos funciona con demasiado ruido?

En primer lugar, compruebe si la máquina está colocada suavemente para asegurarse de que no haya vibraciones. Si la máquina se coloca de manera desigual, puede provocar un aumento del ruido. En segundo lugar, compruebe si las piezas móviles están desgastadas o faltan aceite, lubrique o reemplace las piezas desgastadas si es necesario.

El efecto de separación no es satisfactorio, el líquido del huevo no se separa completamente de la cáscara del huevo.

Compruebe si se están poniendo demasiados huevos en la entrada al mismo tiempo y asegúrese de que solo se procese la cantidad correcta de huevos a la vez.

Aparece óxido en el equipo después de la limpieza, ¿cómo solucionarlo?

Asegúrese de que la máquina para romper huevos comercial se limpie adecuadamente después de cada uso, especialmente en ambientes húmedos, y se seque rápidamente. O use aceite antioxidante para cubrir las áreas propensas a oxidarse para mayor protección.