La ligne de production de poudre de carotte peut traiter une variété de matières premières de fruits et légumes selon vos besoins, avec une forte adaptabilité et une continuité de production. Le haut degré d'automatisation de la ligne de production de poudre de carotte peut grandement économiser la main-d'œuvre et les coûts d'exploitation.

Cela peut également garantir l'hygiène du processus de production, et assurer la sécurité et la fiabilité des produits. La capacité de la ligne de production de poudre de carotte varie de 50 à 2000 kg/h et peut être personnalisée selon les besoins.

Caractéristiques techniques de l'usine de traitement de poudre de carotte

- Automatisation et intelligence. Ligne de production de poudre de carotte, depuis le transport des matières premières jusqu'à l'emballage du produit fini, l'ensemble du processus de production automatisée, réduisant considérablement les coûts de main-d'œuvre, pour obtenir une production efficace.

- Conception d'économie d'énergie et de protection de l'environnement. Le processus de séchage et de concassage réduit considérablement la consommation d'énergie et la pollution de l'environnement en optimisant l'utilisation de l'énergie thermique et des dispositifs de récupération des poussières, ce qui répond aux exigences d'une production verte.

- Exigences d'hygiène élevées. L'ensemble de la chaîne de production est en acier inoxydable de qualité alimentaire et les zones de processus clés sont entièrement scellées pour empêcher efficacement la contamination croisée et répondre aux normes internationales d'hygiène alimentaire.

- Service personnalisé. Nous pouvons formuler un plan détaillé pour l'ensemble de la ligne de production en fonction du résultat demandé par les clients et maintenir une communication étroite avec les clients tout au long du processus, en tenant pleinement compte du bon effet de production de la ligne de production et de la réduction des coûts d'entrée.

Processus de fabrication de poudre de carotte

Le processus principal de la production de poudre de carotte jusqu'à l'emballage est le nettoyage – l'épluchage – le tranchage – le séchage – le broyage – l'emballage.

L'ensemble de la ligne de production de poudre de carotte comprend des machines : machine de nettoyage de carottes – machine à éplucher – machine à trancher – machine à sécher – machine à broyer la poudre – machine à emballer la poudre.

L'ensemble du processus de production est relativement simple et le coût d'investissement est relativement faible. Ce qui suit est l’introduction détaillée de la machine de l’usine de traitement de poudre de carotte.

Machines de traitement de poudre de carotte

Machine à laver les carottes

Cette machine à laver les carottes est équipée d'une fonction d'épluchage. Elle permet d'obtenir des carottes propres après que les carottes fraîches aient été lavées par pulvérisation et épluchées par un tambour à brosse dure. Elle dispose d'un système de drainage pour un nettoyage et un entretien faciles.

Machine à éplucher les carottes

Cette machine à éplucher les carottes possède plusieurs ensembles de lames à l'intérieur pour un épluchage à 360°. Elle est capable d'alimenter, d'éplucher et de décharger automatiquement, avec une efficacité d'épluchage rapide et des résultats d'épluchage uniformes et plats. Elle évite les inconvénients d'une faible efficacité, d'un effet d'épluchage incohérent et d'une perte de coût élevée de l'épluchage manuel.

Machine à trancher les carottes

Grâce à la machine à trancher les carottes coupées en morceaux de taille définie, pour améliorer l'efficacité du séchage. Cette trancheuse puissante est également capable de changer de lames pour couper en dés, en tranches et en bâtonnets de carottes. Les clients peuvent choisir la forme de coupe en fonction de leurs besoins.

Machine de déshydrateur de carotte

La machine de séchage est l'un des processus clés de la production de poudre de carotte. Les équipements de séchage couramment utilisés comprennent une salle de séchage et un séchoir à bande. Parmi eux, la salle de séchage a un coût inférieur et la taille de la machine peut être personnalisée en fonction de l'efficacité de la production. Le séchoir à bande est plus cher, mais il peut réaliser un séchage continu. (En savoir plus : machine à sécher les oignons)

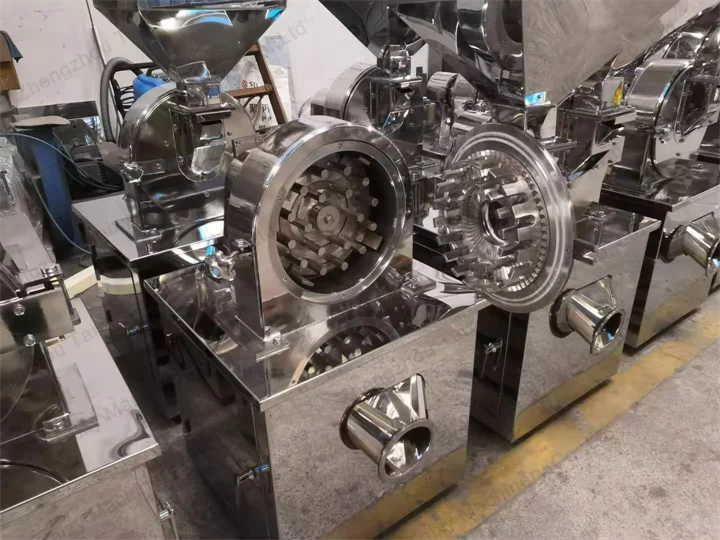

Machine de concassage de poudre de carotte

Cette machine de broyage de poudre adopte la méthode de broyage par impact. Le matériau est broyé dans la chambre de broyage par l'impact d'un corps de marteau en rotation à grande vitesse. Ensuite, le matériau entre dans le sac de collecte à travers le trou de tamis, ne laissant aucun résidu. La taille des particules finies peut être sélectionnée entre 20 et 120 mesh. La machine peut être équipée d'un séparateur cyclonique et d'un dépoussiéreur, de sorte qu'aucune poussière ne vole pendant le processus de production et réduit le taux de perte des matériaux.

Machine de conditionnement de poudre de carotte

Enfin, la poudre de carotte est emballée par remplissage et scellage automatiques de la machine d'emballage de poudre. Cette machine d'emballage de poudre intelligente et avancée permet un réglage continu des paramètres d'emballage. Elle est précise dans le dosage, facile à utiliser et prend en charge une variété d'accessoires personnalisés pour améliorer le degré d'automatisation.

Informations techniques des machines de traitement de poudre de carotte

| Modèle | Pouvoir | Taille | Poids |

| Machine à laver les carottes | 1,1 kW | 1580*850*800mm | 180 kg |

| Machine à éplucher les carottes | 500w | 1980*450*1050mm | 120 kg |

| Machine à trancher les carottes | 0,75 kW | 750*520*900mm | 70 kg |

| Machine de séchage de carottes | 4000*1600*2500mm | ||

| Machine de concassage de poudre de carotte | 2,2 kW | 150 kg | |

| Machine de conditionnement de poudre de carotte | 2,2 kW | 1100*750*1820mm | 280 kg |

Ci-dessus se trouve l’introduction d’informations sur certains paramètres de l’équipement de l’usine de traitement de la poudre de carotte. Si vous souhaitez connaître des informations plus détaillées sur les machines, vous pouvez nous contacter dès maintenant pour les obtenir immédiatement.

Prix de la ligne de production de poudre de carotte

Le coût d'investissement en équipement de l'usine de traitement de poudre de carotte comprend principalement l'équipement principal et l'équipement auxiliaire (bande transporteuse, dépoussiéreur, dispositif de récupération de chaleur).

Nous pouvons personnaliser les machines de la ligne de production et analyser le coût de la ligne de production en fonction de la capacité de traitement du client. Bienvenue à nous consulter !

Perspectives d’application de la poudre de carotte

Avec la croissance continue de la consommation d’aliments santé, la poudre de carotte est devenue une matière première importante dans le domaine de la transformation alimentaire. Dans les domaines des boissons fonctionnelles, des soupes instantanées, des aliments pour bébés et des produits de santé, la poudre de carotte est privilégiée pour son caractère naturel et sa valeur nutritionnelle.

En outre, la technologie de la chaîne de production de poudre de carotte peut également être étendue au traitement d’autres poudres de fruits et légumes afin d’élargir davantage l’espace de marché. Par exemple, poudre de gingembre, poudre d'ail, poudre de banane, poudre d'épices, etc.

Comment contrôler la perte de couleur et de nutriments de la poudre de carotte pendant la production ?

Contrôle de la température : une température trop élevée pendant le séchage peut facilement entraîner un assombrissement de la couleur de la poudre de carotte et une perte de vitamine A et d'autres nutriments. Afin de conserver la couleur et la nutrition, une plage de température appropriée (par exemple 40-60℃) doit être choisie pour le séchage à basse température.

Ajout d'antioxydants : afin d'éviter l'oxydation et la décoloration des ingrédients naturels de la poudre de carotte, des antioxydants tels que la vitamine C peuvent être ajoutés en quantités appropriées pour ralentir la réaction d'oxydation.

Refroidissement rapide : le refroidissement est effectué immédiatement après le séchage pour réduire l'effet secondaire de la haute température sur la poudre et maintenir la couleur et la nutrition.

Méthodes de maintenance des machines de traitement de poudre de carotte

- Nettoyage et maintenance : Nettoyez régulièrement les machines, en particulier le sèche-linge, le broyeur et d'autres pièces en contact direct avec le produit, pour éviter que les impuretés et résidus n'affectent l'efficacité de la production et la qualité du produit.

- Lubrification et inspection : Vérifiez la lubrification des pièces de transmission et remplacez le lubrifiant à temps pour assurer le bon fonctionnement des machines.

- Inspection de l'équipement : Vérifiez régulièrement le système électrique et les pièces mécaniques des machines, telles que le dispositif de transmission, le système de chauffage, le ventilateur, etc., pour assurer le bon fonctionnement de chaque pièce.

- Dépannage : Pour les bruits anormaux, vibrations ou anomalies de température des machines, effectuer rapidement des dépannages pour éviter que de petits problèmes ne provoquent un arrêt de la production.

FAQ

Quelles machines sont incluses dans cette ligne de production de poudre de carotte ?

Machine de lavage à brosse → Éplucheuse de carottes → Machine de broyage → Four de séchage → Machine d'emballage de poudre.

Quelle capacité la ligne supporte-t-elle ?

De 50 à 2000 kg/h, en fonction de la taille de la machine et de la capacité de séchage.

Quelle est la teneur en humidité après le séchage ?

Typiquement réduit à ≤8 %, adapté au stockage à long terme et à la production commerciale de poudre.

La ligne est-elle facile à utiliser ?

Oui. 2 à 4 travailleurs suffisent pour une ligne standard.

La ligne de production peut-elle traiter d'autres légumes ?

Oui. Elle peut également traiter le gingembre, la betterave, la courge, l'oignon, la pomme de terre, etc.

Quel support après-vente fournissez-vous ?

Manuels d'utilisation, guide d'installation, pièces de rechange et support technique à vie.