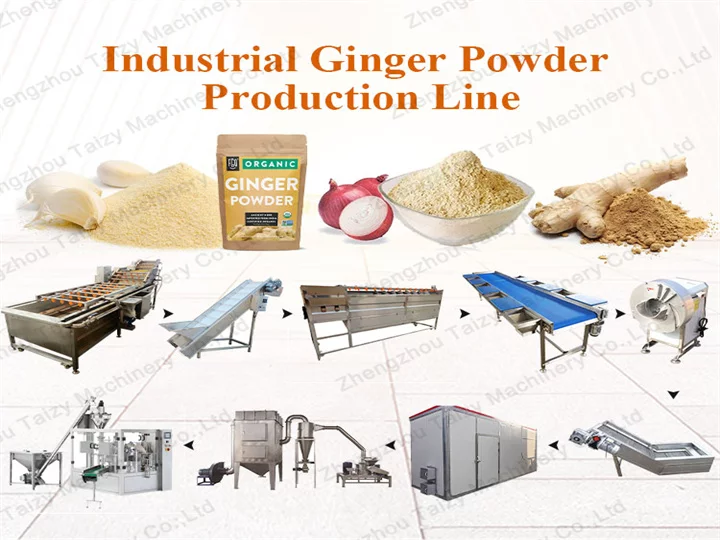

Машины для обработки имбиря представляют собой полный набор машин, специализирующихся на переработке имбиря в имбирный порошок, в основном включая стиральную машину для имбиря, машину для нарезки имбиря, сушилку для имбиря, измельчитель имбиря и упаковочную машину для имбиря. Они могут обеспечить эффективную обработку и непрерывное производство свежего имбиря и имбирного порошка. Высокоавтоматизированная линия по производству порошка имбиря значительно повышает эффективность производства и снижает потребление рабочей силы, материальных ресурсов и времени. Наконец, это может принести предприятию богатую экономическую выгоду!

Преимущества линии по производству имбирного порошка, на которую стоит инвестировать

- Высокая эффективность и низкие затраты. Автоматизированная линия по производству порошка имбиря обеспечивает непрерывную работу, значительно повышает эффективность производства и сокращает трудозатраты и время.

- Производство высококачественного имбирного порошка. Передовые технологии обработки и производства обеспечивают высокую чистоту, прекрасный вкус и отсутствие потерь питательных веществ имбирного порошка.

- Работа с разнообразным сырьем. Его можно использовать не только для изготовления всех видов имбирного порошка, но также для обработки многих видов растительного порошка, таких как луковый порошок, чесночный порошок, морковный порошок и так далее.

- Поддержка настройки производственной линии. Мы можем настроить эффективность обработки, степень автоматизации и характеристики упаковки производственной линии в соответствии с потребностями каждого клиента, чтобы удовлетворить потребности разных клиентов.

- Защита окружающей среды и энергосбережение. Вся производственная линия реализует концепцию энергосбережения и защиты окружающей среды для снижения энергопотребления. Линия также оснащена устройством очистки сточных вод и плавающим порошком.

Процесс изготовления имбирного порошка

Как превратить свежий имбирь в имбирный порошок и, наконец, реализовать упаковку порошка?

Производственный процесс линии по производству имбирного порошка в основном включает этапы подготовки сырья, очистки, очистки, нарезки, сушки, измельчения и упаковки.

Основное оборудование линии по производству сухого порошка имбиря

Это щеткомоечная машина для имбиря из нержавеющей стали Brush type ginger washer, специально разработанная для имбиря, которая может легко обеспечить эффект мытья и очистки. Машина эффективно удаляет почву, примеси и остатки пестицидов со свежего имбиря, а также удаляет кожуру имбиря с помощью распылительного устройства и жестких щеток. Машина для мойки имбиря среднего размера может обрабатывать 1500 кг/ч.

Машина для нарезки имбиря ginger chips cutting machine быстро нарезает имбирь на ломтики одинаковой толщины с гладкой поверхностью резки благодаря высокоскоростному вращающемуся лезвию. Универсальная машина для нарезки имбиря позволяет не только регулировать толщину нарезки, но и менять лезвия для нарезки имбиря соломкой.

Внутренняя часть машины для сушки имбиря ginger drying machine, контактирующая с материалом, изготовлена из нержавеющей стали для обеспечения гигиены пищевых продуктов. Она использует систему циркуляции горячего воздуха, что обеспечивает быструю сушку и экономию энергии. Также имеется автоматическая система контроля температуры для обеспечения стабильного и точного контроля температуры.

После высокоэффективного измельчения ginger powder grinder высушенные ломтики имбиря измельчаются в мелкий и однородный имбирный порошок на высокой скорости. Размер частиц имбирного порошка может быть выбран в диапазоне 20-120 меш путем замены сита. После измельчения вибрационная просеивающая машина также может использоваться для просеивания грубого порошка и примесей, чтобы получить готовый имбирный порошок с постоянным контролем качества.

Имбирный порошок упаковывается, измеряется, наполняется, запечатывается, нарезается и подсчитывается с высокой эффективностью с помощью автоматизированной упаковочной машины для имбирного порошка fully automatic packaging machine. Она использует передовую систему управления микрокомпьютером с двумя ЦП, точное измерение и точную резку. Также имеется выбор различных методов запечатывания, таких как задняя герметизация, трехсторонняя герметизация, четырехсторонняя герметизация и так далее.

Продажа машин для производства имбирного порошка

| Имя машины | Имбирь Шайба | Имбирь Слайсер | Имбирь Сушилка | Мельница для порошка имбиря | Машина для упаковки имбирного порошка |

| Мощность (кВт) | 1.5 | 1.1 | 12.45 | 7.5 | 1 |

| Напряжение | 380В50Гц | 380В50Гц | 380В50Гц | 380В50Гц | 380В50Гц |

| Размер (мм) | 1580*850*800 | 690*560*880 | 1500*1200*2200 | 700*600*1450 | 1000*900*1850 |

Выше приведена информация о параметрах основных машин в процессе изготовления имбирного порошка, которую вы можете использовать в качестве справки. Если вы хотите узнать более подробную информацию о машинах, пожалуйста, свяжитесь с нами.

Реальная выставка машин для обработки порошка имбиря

Как правильно выбрать оборудование для обработки порошка имбиря?

Мы предлагаем машины для переработки порошка имбиря разных размеров. Следующие предложения могут дать вам рекомендации по выбору подходящего масштаба производства и оборудования:

- Производственный спрос: вам следует выбрать правильный размер машин в соответствии с ежедневным производственным спросом.

- Степень автоматизации: высокая автоматизация подходит для крупных предприятий, а низкая автоматизация подходит для малых предприятий с ограниченным бюджетом.

- Материал оборудования: машины из пищевой нержавеющей стали больше подходят для обработки пищевых продуктов, чтобы обеспечить безопасность и гигиену.

- Квалификация поставщика: вы можете выбрать производителей с хорошей репутацией и отличным послепродажным обслуживанием.

Цена инвестирования в завод по переработке порошка имбиря

Цена производственной линии по производству имбирного порошка зависит от конфигурации машины, производительности и степени автоматизации. На цену также влияют бренд, материал производственной линии (например, марка нержавеющей стали), послепродажное обслуживание и другие факторы.

Если вы хотите узнать больше о цене машин для обработки порошка имбиря, вы можете отправить нам информацию о мощности обработки и индивидуальные требования. Мы свяжемся с вами в течение 12 часов и подберем для вас экономически эффективное решение производственной линии.

О чем нужно помнить при производстве имбирного порошка?

Контроль качества сырья. Чтобы имбирь не покрывался плесенью, чтобы не повлиять на качество готового продукта.

Контроль температуры. Во время сушки и измельчения необходим соответствующий контроль температуры, чтобы избежать разрушения активных ингредиентов имбиря при высокой температуре.

Чистка и дезинфекция. Все машины, контактирующие с пищевыми продуктами, необходимо регулярно очищать, чтобы избежать перекрестного загрязнения.