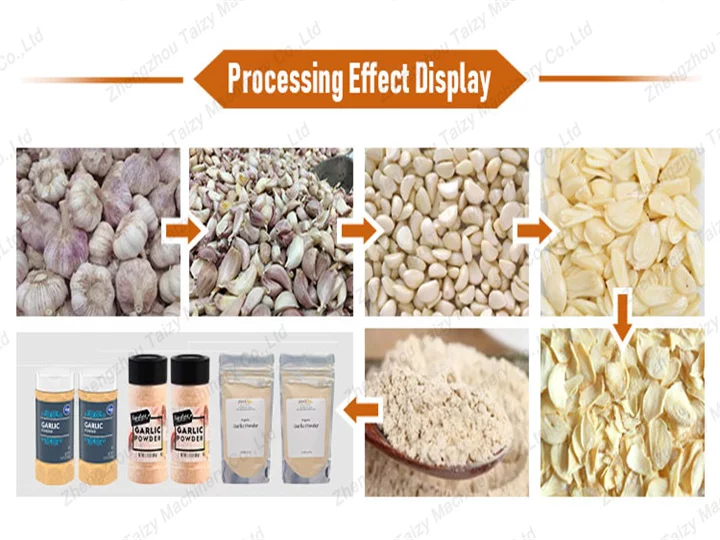

Garlic powder making plant retains the natural flavor and nutrients of garlic to the maximum extent through automatic cleaning, slicing, and drying. The crushing and sieving machines ensure the fineness and purity of garlic powder, and the intelligent packaging machine completes the automatic filling, sealing, and labeling.

The whole garlic powder production line is made of food-grade stainless steel, which ensures the high quality of garlic powder and production safety and hygiene at the same time.

마늘 가루 만들기 과정은 무엇입니까?

마늘분말 생산부터 포장까지의 주요 공정은 마늘 정향 분리, 껍질 벗기기, 세척, 썰기, 건조, 분쇄, 포장 등의 과정을 거친다.

다음 부분은 주요 기계에 대한 자세한 소개입니다.

마늘분말 제조공장의 장비구성

마늘 전구 분리 기계

마늘 분리기는 내부 롤러를 사용하여 손으로 마늘을 벗기는 동작을 모방하여 마늘 쪽을 분리합니다. 이 기계는 마늘 쪽을 손상시키지 않고 효율적으로 (최대 98% 이상) 분리합니다. 팬이 자동으로 마늘 쪽을 마늘 껍질로부터 분리하여 깨끗한 완제품을 만듭니다.

마늘 껍질 필러

Automatic and high-efficiency garlic skin peeling equipment. It can peel 200-500 kg/h, and the peeling effect is good. This machine greatly avoids the slow peeling and unclean peeling effect of manual peeling. In addition to garlic, it can also peel other materials such as onion, hazelnut, peanut, etc. It has wide applicability.

마늘 세탁기

The garlic washer adopts a bubble and high-pressure spray design to clean the soil and dirt of garlic skin in all directions. It not only cleans all kinds of fruits and vegetables, but also bags, meat, and other products. It ensures cleanliness while cleaning quickly. The internal water circulation system can save water resources and realize energy saving and environmental protection.

마늘 슬라이싱 기계

Compared with the slices cut by hand, the garlic slicing machine cuts a smoother surface and uniform thickness. The structure of the machine is simple, sturdy, and durable. The use of stainless steel blades ensures that the food is clean, hygienic, and easy to clean.

마늘 탈수기 기계

우리는 마늘 슬라이스를 건조할 수 있는 다양한 건조기를 판매하고 있습니다. 예를 들어, 건조실, 메쉬 벨트 건조기 등이 있습니다. 건조실의 가격은 상대적으로 낮고, 메쉬 벨트 건조기의 가격은 상대적으로 높습니다. 마늘 건조기는 안정적인 건조 품질로 재료를 건조하기 위해 열풍 순환을 이용합니다.

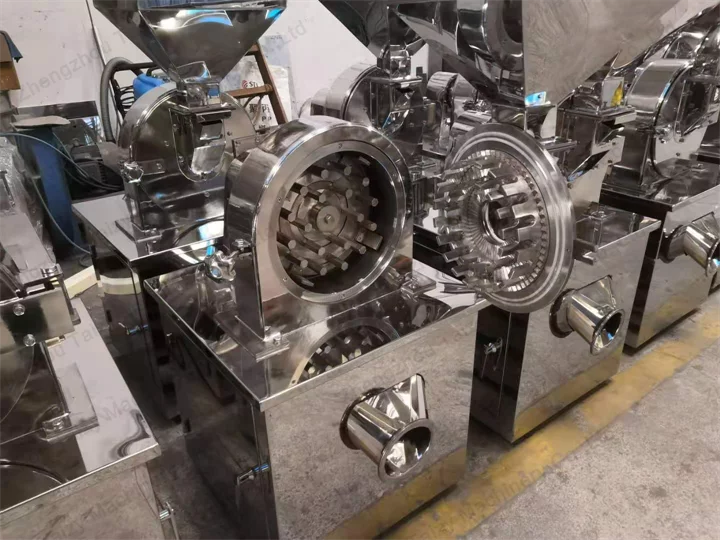

마늘 조각 연삭기

The garlic powder maker is made of 304 stainless steel, so it is smooth and not easy to clog. It can crush all kinds of dry materials into powder, and customers can choose the size of the finished product according to the replacement of the screen size. Its output range is between 20-3000kg/h.

마늘 분말 채우기 밀봉 포장 기계

The garlic powder packaging machine can automatically realize bag making, filling, sealing, and cutting. It only needs to feed the garlic powder evenly into the feeding port, so one person can operate it. It can also be customized with coding machines, screw conveyor, easy-tear opening, inflating, exhausting, dust-absorbing, and other devices to improve automation.

If you’re interested in our garlic powder production line after reading this, contact us today for detailed information!

마늘 가루 생산 라인의 선택 기계

컨베이어

원료나 가공된 마늘편, 마늘분말 등을 다음 가공단계로 이송하는데 사용되어 수작업으로 인한 취급비용을 절감합니다. 우리는 다양한 재료의 운송 요구를 지원하기 위해 마늘 분말 제조 공장에 따라 올바른 모델을 구성할 수 있습니다.

색상 분류기

High-precision testing equipment. The color sorter can automatically screen out impurities, discoloration, or poor-quality garlic slices to improve the quality of finished products. It is especially suitable for processing enterprises that require high quality product appearance.

왜 마늘 가루 제조 공장을 갖고 있나요?

- 품질 보증. 전체 마늘 가루 생산 라인은 식품 안전 표준에 따라 식품 등급의 스테인레스 스틸로 만들어졌습니다. 그리고 생산된 마늘가루는 순도가 높고 맛이 좋습니다.

- 유연하고 맞춤화된 콘텐츠. 구성된 가공 라인 기계는 고객의 요구에 따라 출력에 따라 조정될 수 있습니다. 그리고 각 장비는 고객에게 최고 품질의 생산 라인 장비를 제공하기 위해 맞춤화를 고집합니다.

- 완벽한 애프터 서비스. 고품질 기계를 구매하신 후, 기계는 1년간 보증 기간이 제공됩니다. 또한, 저희 전문 기술자들이 고객님께서 가공 라인에 대해 문앞까지 설치, 기술 지원, 운영 교육 서비스를 제공할 수 있습니다.

- 고효율 및 낮은 에너지 소비. 빠르고 효율적인 처리를 위한 완전 자동화된 작업입니다. 전체 프로세스를 완료하는 데 약간의 노동력만 필요합니다. 동시에 우리 기계는 에너지 절약 개념을 고수하여 에너지 소비를 줄입니다.

마늘분말 제조공장의 비용 분석

The cost of a garlic powder-making plant varies according to machine configuration, output scale, automation degree, brand awareness, after-sales service, and additional machines.

마늘 분말 생산 라인의 구체적인 가격을 원하시면 기계 처리 능력과 수요를 보내주십시오. 귀하가 요구하는 생산 규모에 대한 비용 분석을 수행합니다.

What Needs to Be Considered during the Production of Garlic Powder?

원료 품질 관리. 마늘에 곰팡이가 생기지 않도록 하고 완제품의 품질에 영향을 주지 않도록 합니다.

Temperature control. Appropriate temperature control is needed during drying and crushing to avoid high temperatures destroying the active ingredients of garlic.

Cleaning and sanitizing. All food contact machines must be cleaned regularly to avoid cross-contamination.

자주 묻는 질문

마늘 가루 가공 공장은 다른 재료의 가공을 지원합니까?

마늘 가루 생산 라인은 생강 가루, 고춧가루, 양파 가루 등 대부분의 건조 재료 가공과 호환됩니다.

건조 과정이 마늘의 영양분을 파괴합니까?

The garlic dryer adopts low-temperature drying technology to maximize the retention of garlic’s nutrients and natural flavor. It also ensures that the moisture content meets food preservation requirements.

마늘 가루 제조 공장의 유지 비용이 높은가요?

주로 장비 청소, 마모 부품(예: 체 및 블레이드) 교체, 정기적인 정밀 검사를 포함하여 유지 관리 비용이 저렴합니다.

문의하기!

The best machines aren’t just products sold to you—they’re partners that grow alongside your business. If you’d like professional advice tailored to your specific needs, contact our expert team today. We offer customized solutions.