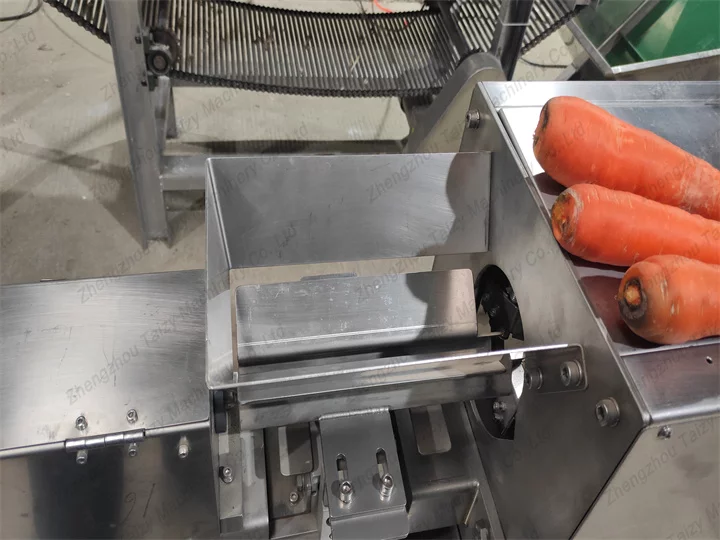

La peladora automática de zanahorias puede quitar de manera eficiente y rápida la piel exterior de zanahorias, lechugas, ñames y otros materiales con ocho juegos de cuchillas de acero inoxidable. La máquina peladora de zanahorias de Taizy puede procesar 1500 zanahorias por hora, lo que mejora enormemente la eficiencia del procesamiento. Y las zanahorias peladas quedan lisas y planas, fáciles de vender después.

Amplia aplicabilidad del removedor de piel de zanahoria

La máquina quita piel de zanahoria puede pelar la piel de muchos materiales. Por ejemplo, rábano blanco, espárragos, raíz de loto, pepino, ñame, remolacha, etc.

La máquina peladora automática de zanahorias es adecuada para la industria de comida rápida, supermercados, comedores a gran escala, plantas procesadoras de la industria alimentaria, etc.

Video de la máquina peladora de zanahorias comercial en funcionamiento

¿Por qué elegir una peladora automática de zanahorias?

- Peeling integral de 360 grados. Los ocho juegos de cuchillas están hechos de acero inoxidable 304, material de pelado rápido y afilado desde diferentes ángulos.

- La eficiencia de pelado es superior a 98%. Velocidad de alimentación automática, alta eficiencia de pelado.

- Menos pérdida de costos. El éxito del pelado una sola vez reduce el consumo de mano de obra y material.

- Buen efecto peeling. La superficie del material pelado es lisa, uniforme y plana.

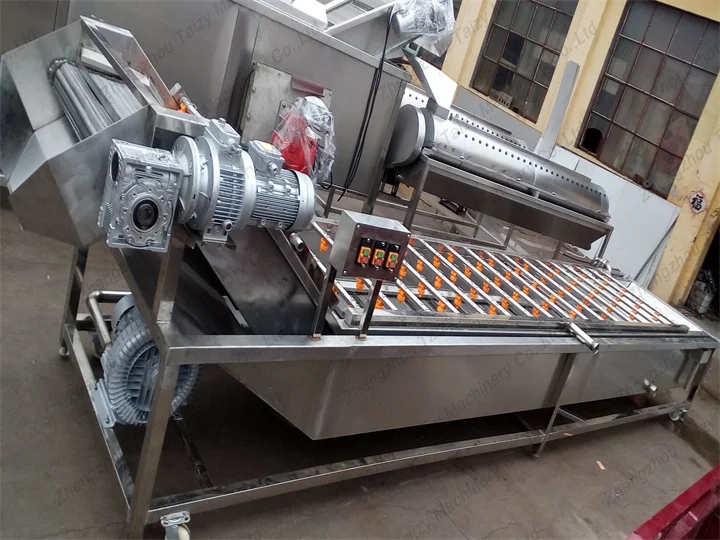

- Fácil de mover. Con ruedas móviles, fácil de mover. Se puede utilizar con la línea de producción.

- Fácil de limpiar y mantener. La superficie de la máquina es lisa y fácil de limpiar, garantizando la seguridad alimentaria. Material de alta calidad, anticorrosión y resistente a la humedad.

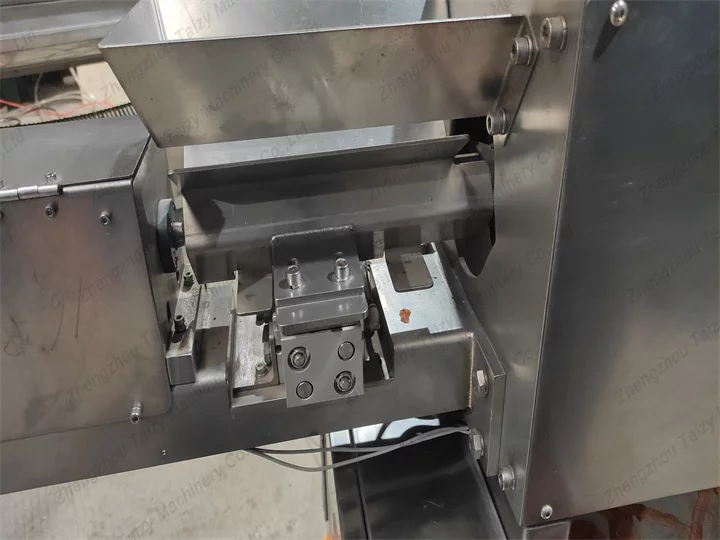

Piezas industriales de la máquina peladora de zanahorias

La estructura de la máquina quitapelusas de zanahorias consta principalmente de 8 juegos de cuchillas, una cubierta protectora de cuchillas, una entrada, una salida, un panel de control, una salida peladora y otras piezas.

Información de parámetros de la máquina peladora de zanahorias

Capacidad: 1500 piezas/h

Tamaño: 1980*450*1050mm

Peso: 120 kg

Voltaje: 220v

Potencia: 500w

Material: acero inoxidable 304

Además de esta máquina peladora automática de zanahorias, también tenemos la máquina limpiadora de zanahorias, máquina lavadora y peladora de zanahorias a la venta. ¡No dude en contactarnos para obtener los últimos precios, ofertas especiales y personalización de equipos!

Taizy: un proveedor profesional de máquinas procesadoras de alimentos

- Soporte técnico profesional. Con 13 años de experiencia en investigación y desarrollo, brindamos una gama completa de servicios de consultoría técnica y personalización de equipos para satisfacer las necesidades de los clientes en diferentes industrias.

- Garantía de calidad del producto. La máquina peladora de zanahorias se somete a estrictos controles de calidad y pruebas para garantizar que cada equipo cumpla con los estándares internacionales.

- Perfecto servicio postventa. Brindamos a nuestros clientes un servicio posventa de 7 × 24 horas para garantizar que puedan obtener soluciones oportunas cuando hay problemas con la máquina. Y la máquina tiene un año de garantía.

- Soluciones personalizadas. Podemos brindar servicios de personalización personalizados de acuerdo con las necesidades del cliente, incluida la capacidad de procesamiento del equipo, las funciones y el diseño de apariencia para garantizar que los productos puedan maximizar las necesidades de producción.

¿Dónde conseguir una peladora de zanahorias?

Hay varias formas de comprar peladoras automáticas de zanahorias:

Plataforma en línea. Puede encontrar fabricantes de máquinas peladoras de zanahorias en muchos países en plataformas en línea, como Alibaba, Amazon, etc.

Sitio web de proveedores de maquinaria profesional. Puede navegar por los sitios web de varios proveedores de maquinaria en Google para comparar fácilmente precios y características.

Exposición de maquinaria alimentaria. Puede asistir a ferias comerciales relevantes de la industria para conocer a los fabricantes cara a cara y conocer los últimos equipos y tecnologías.

Distribuidores locales de maquinaria industrial. Puede ponerse en contacto con distribuidores o agentes locales de maquinaria industrial especializados para brindar servicios personalizados y obtener información detallada sobre compras y precios.

Métodos de mantenimiento de la máquina para quitar la piel de zanahoria

Limpieza periódica

Después de cada uso, limpie todas las partes de la máquina peladora de zanahorias comercial de manera oportuna, especialmente el juego de cuchillos peladores y la entrada de alimento, para evitar la acumulación de residuos de alimentos.

Comprobar piezas mecánicas

Revise periódicamente las cuchillas de la peladora de zanahorias de acero inoxidable para asegurarse de que no presenten daños ni desgaste. Si están dañados, reemplácelos de inmediato.

Inspección del sistema de control eléctrico

Verifique periódicamente las conexiones del cableado del sistema de control eléctrico para garantizar que el equipo eléctrico funcione correctamente y evitar fallos de funcionamiento eléctricos.

Inspección periódica de dispositivos de seguridad

Asegúrese de que los dispositivos de protección de la máquina estén intactos para garantizar la seguridad del operador.