La máquina cortadora automática de zanahorias puede cortar de manera eficiente y precisa el tamaño de partículas entre 3 y 30 mm. No solo la alta eficiencia reduce en gran medida el costo de mano de obra, sino que también se garantiza que el tamaño de las partículas será estable y uniforme. La máquina cortadora de cubitos de zanahoria es muy rentable y ahora se usa ampliamente en todo tipo de procesamiento de alimentos y en el campo de la restauración.

¿A qué áreas se puede aplicar la máquina cortadora de cubos de zanahoria?

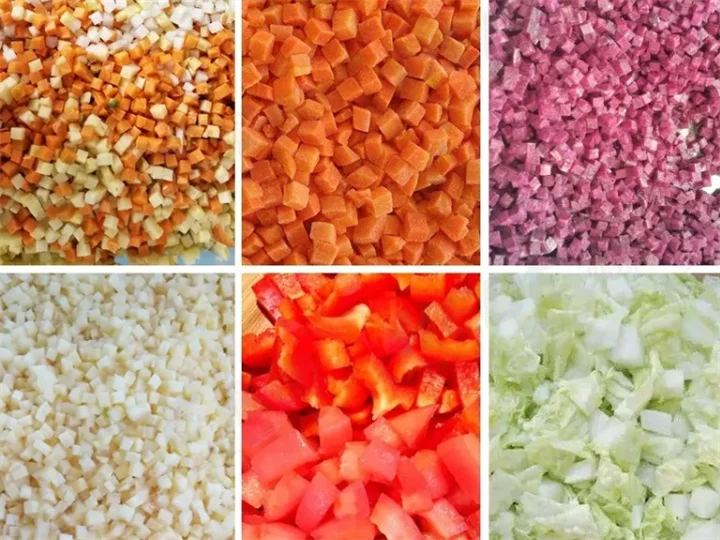

La máquina cortadora automática de zanahorias de Taizy puede cortar y manipular una amplia variedad de frutas y verduras con una amplia gama de aplicaciones. Por ejemplo, zanahorias, patatas, taro, batatas, pepinos, cebollas, pimientos, tomates y otras verduras. Mango, piña, papaya, manzana, fresa y otras frutas.

La máquina cortadora de zanahorias también tiene una amplia gama de aplicaciones y puede usarse de manera flexible. Se puede utilizar en una variedad de lugares, como plantas procesadoras de alimentos, hoteles, restaurantes, comedores escolares, restaurantes de comida rápida, cafeterías, procesamiento agrícola y distribución de cadena de frío.

Características de la Cortadora de Zanahorias

- El tamaño de corte es ajustable. Hay más de diez tamaños para elegir, por lo que los clientes pueden ajustar el tamaño de los pellets de zanahoria según sus necesidades.

- Multifuncionalidad. Además de cortar zanahorias en cubitos, los clientes pueden obtener rodajas y palitos de zanahoria reemplazando los cuchillos.

- Corte preciso. La máquina cortadora de zanahorias está equipada con un sistema de herramientas de precisión que garantiza consistencia y estandarización de los resultados de corte.

- Ahorro de costes laborales. En lugar de las deficiencias del efecto de corte inestable y que requiere mucho tiempo de corte manual tradicional, su operación puede garantizar una mayor productividad y estabilidad, y reducir la intensidad del trabajo manual.

- Ahorro de energía. La máquina cortadora de zanahorias adopta un motor de alta eficiencia, que puede reducir efectivamente el consumo de energía.

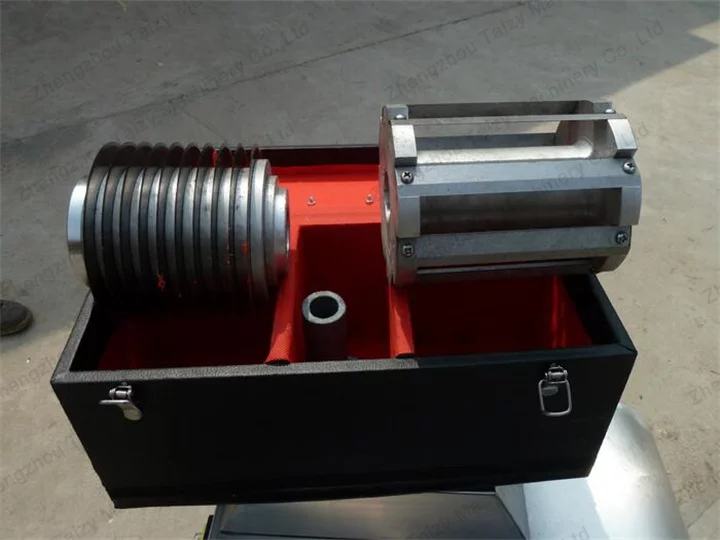

Estructura de la máquina automática de dados de zanahorias

Máquina cortadora de zanahorias comercial a la venta

| Modelo | TZ-350 | TZ-550 |

| Tamaño de la máquina (mm) | 1500*700*1000 | 1940*980*1100 |

| Tamaño de la ranura de corte (mm) | 84*84*350 | 120*120*550 |

| Longitud máxima de carga (mm) | 350 | 550 |

| Tamaño mínimo de corte en cubitos (mm) | 3-4 | 3-4 |

| Tamaño máximo de corte en cubitos (mm) | 30 | 30 |

| Tamaño de la rejilla de corte (mm) | 5;6;7;9;11;14;16;19 | 5;6;7;9;11;14;16;19 |

| Potencia (kilovatios) | 2.2 | 2.2 |

| Capacidad (kg/h) | 500-600 | 700-900 |

Si necesita personalizar la máquina automática para cortar zanahorias en cubitos con otra capacidad de procesamiento, puede enviarnos un mensaje. ¡Le responderemos en un plazo de 12 horas!

Además de esto, si desea aumentar el nivel de automatización en el procesamiento de dados de zanahoria, también puede usarla con una lavadora de zanahoria y un pelador de zanahoria.

Fabricante profesional de máquinas de dados de zanahorias

- Ampliamente popular. El cortador de zanahorias en cubitos se ha exportado a más de 10 países, como Estados Unidos, Canadá, Indonesia, Malasia, Tailandia, etc., y es muy apreciado por los clientes.

- Servicio personalizado. Todos podemos brindar un servicio personalizado para clientes de una sola máquina, compras al por mayor o líneas de producción, dedicados a satisfacer las necesidades de producción a diferentes escalas.

- Seguro de calidad. Ofrecemos equipos avanzados de alta calidad y un rico servicio postventa. Nos aseguramos de que nuestros clientes puedan utilizar la máquina sin problemas y extender la vida útil.

- Entrega a tiempo. Tenemos una producción perfecta y logísticoSistema de gestión, entrega a tiempo, corto tiempo de espera.

Casos de cooperación exitosos

Métodos de limpieza y mantenimiento

Limpieza periódica. El cortador de cubos de zanahoria debe limpiarse periódicamente, especialmente después de cada uso, limpiar el sistema de corte, la entrada, la salida y otras partes. Evite residuos de ingredientes y garantice la higiene del equipo.

Revisa los cuchillos. Los cuchillos son las partes clave de la máquina cortadora de zanahorias, por lo que se debe comprobar periódicamente el filo de los cuchillos. Reemplácelos o afílelos cuando sea necesario para garantizar el efecto de corte.

Sistema de lubricación. Revise y llene periódicamente el sistema de transmisión con aceite lubricante para evitar daños a las piezas mecánicas debido a la fricción.

Revisión del sistema de control eléctrico. Verifique periódicamente el estado de funcionamiento del sistema de control eléctrico para garantizar la precisión y estabilidad del sistema de control.

Entorno de almacenamiento. Cuando no esté en uso, la máquina cortadora de zanahorias debe almacenarse en un lugar seco y ventilado para evitar que la humedad o el calor afecten el funcionamiento normal del equipo.