Kiwanda cha kutengeneza poda ya kitunguu saumu huhifadhi harufu asilia na virutubisho vya kitunguu saumu kwa kiwango kikubwa kupitia usafi wa kiotomatiki, kukatwa kwa vipande, na ukavu. Mashine za kusaga na kusafisha hufanikisha unene na usafi wa poda ya kitunguu saumu, na mashine ya ufungaji yenye akili inakamilisha kujaza, kufunga, na kuweka lebo kiotomatiki.

Mstari wote wa uzalishaji wa poda ya kitunguu saumu umetengenezwa kwa chuma cha pua cha kiwango cha chakula, ambacho kinahakikisha ubora wa juu wa poda ya kitunguu saumu na usalama na usafi wa uzalishaji kwa wakati mmoja.

Vad är processen för att göra vitlökspulver?

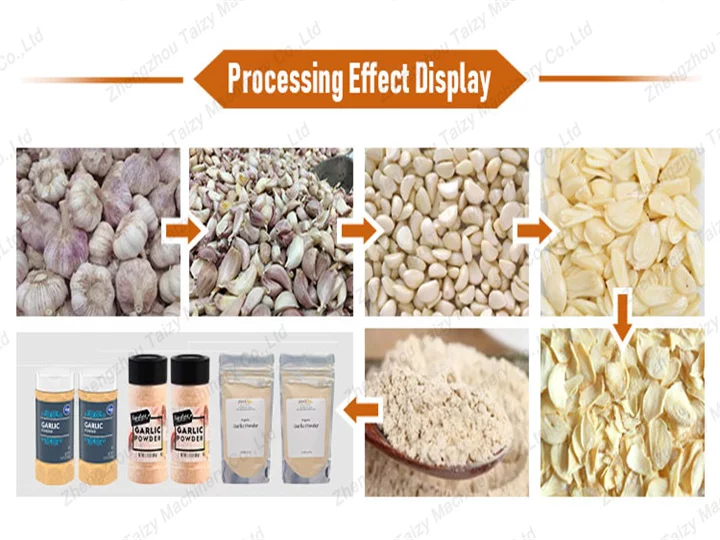

Mchakato mkuu wa uzalishaji wa unga wa vitunguu hadi ufungashaji ni kama ifuatavyo: kutenganisha vitunguu, kuondoa ganda, kusafisha, kukata, kukausha, kusaga, na kufunga.

Sehemu ifuatayo ni utangulizi wa kina wa mashine kuu.

Muundo wa Vifaa vya Kiwanda cha Kutengeneza Unga wa Vitunguu

Mashine ya kutenganisha vitunguu

Mashine ya kutenganisha vitunguu saumu hutumia sana roller ya ndani kuiga hatua ya kukwangua vitunguu saumu kwa mkono ili kutenganisha karafuu za vitunguu saumu. Inatenganisha karafuu za vitunguu saumu kwa ufanisi (hadi 98% au zaidi) bila kuharibu karafuu za vitunguu saumu. Kipeperushi hutenganisha karafuu za vitunguu saumu kutoka kwenye maganda ya vitunguu saumu, na kusababisha bidhaa iliyokamilishwa kuwa safi.

Mashine ya kuondoa ngozi ya vitunguu

Automatic and high-efficiency garlic skin peeling equipment. It can peel 200-500 kg/h, and the peeling effect is good. This machine greatly avoids the slow peeling and unclean peeling effect of manual peeling. In addition to garlic, it can also peel other materials such as onion, hazelnut, peanut, etc. It has wide applicability.

Vitlökstvättmaskin

The garlic washer adopts a bubble and high-pressure spray design to clean the soil and dirt of garlic skin in all directions. It not only cleans all kinds of fruits and vegetables, but also bags, meat, and other products. It ensures cleanliness while cleaning quickly. The internal water circulation system can save water resources and realize energy saving and environmental protection.

Maskin för att skiva vitlök

Compared with the slices cut by hand, the garlic slicing machine cuts a smoother surface and uniform thickness. The structure of the machine is simple, sturdy, and durable. The use of stainless steel blades ensures that the food is clean, hygienic, and easy to clean.

Maskin för att avfukta vitlök

Tunayo aina mbalimbali za kukaushia zinazouzwa, kama vile chumba cha kukaushia, kikaushio cha belt ya mesh, n.k., ambazo zina uwezo wa kukausha vipande vya vitunguu saumu. Bei ya chumba cha kukaushia ni ya chini, na bei ya kikaushio cha belt ya mesh ni ya juu. Kikaushio cha vitunguu saumu hutumia mzunguko wa hewa ya moto kukausha vifaa kwa ubora thabiti wa kukausha.

maskin för malning av vitlökskivor

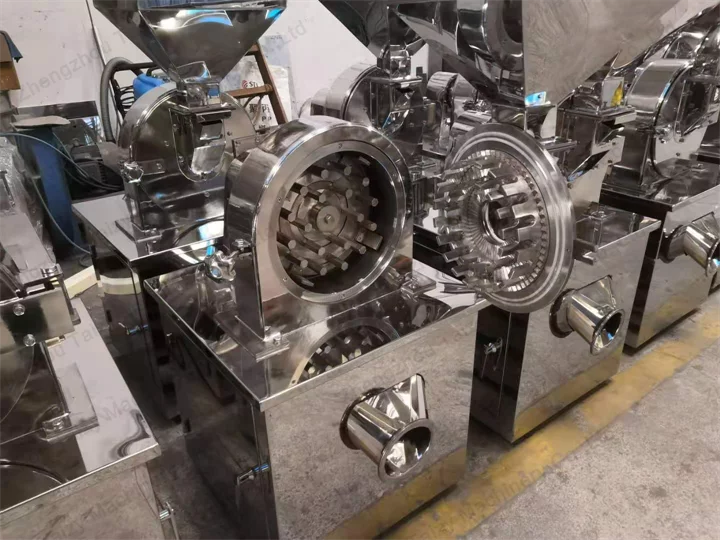

The garlic powder maker is made of 304 stainless steel, so it is smooth and not easy to clog. It can crush all kinds of dry materials into powder, and customers can choose the size of the finished product according to the replacement of the screen size. Its output range is between 20-3000kg/h.

maskin för fyllning och försegling av vitlökspulver

The garlic powder packaging machine can automatically realize bag making, filling, sealing, and cutting. It only needs to feed the garlic powder evenly into the feeding port, so one person can operate it. It can also be customized with coding machines, screw conveyor, easy-tear opening, inflating, exhausting, dust-absorbing, and other devices to improve automation.

If you’re interested in our garlic powder production line after reading this, contact us today for detailed information!

Mashine za Hiari za Mstari wa Uzalishaji wa Unga wa Vitunguu

Transportör

Det används för att transportera råvaror eller bearbetade vitlökskivor och vitlökspulver till nästa bearbetningssteg, vilket minskar kostnaderna för manuell hantering. Vi kan konfigurera rätt modell enligt vitlökspulverproduktionsanläggningen för att stödja transportbehoven för olika material.

Färgsorterare

High-precision testing equipment. The color sorter can automatically screen out impurities, discoloration, or poor-quality garlic slices to improve the quality of finished products. It is especially suitable for processing enterprises that require high quality product appearance.

Varför ha en anläggning för att göra vitlökspulver?

- Dhamana ya ubora. Mstari mzima wa uzalishaji wa unga wa vitunguu umeundwa kwa chuma cha pua cha kiwango cha chakula, kulingana na viwango vya usalama wa chakula. Na unga wa vitunguu unaozalishwa ni wa usafi wa juu na ladha nzuri.

- Yenyo rahisi, yaliyobinafsishwa. Maskinlinjen som har konfigurerats kan justeras i enlighet med utdata enligt kundens efterfrågan. Och varje utrustning insisterar på anpassning för att ge kunderna den bästa kvalitetsproduktionslinjeutrustningen.

- Perfekt efterförsäljningstjänst. Baada ya kununua mashine za ubora wa juu, mashine hizo zina kipindi cha udhamini wa mwaka mmoja. Zaidi ya hayo, wahandisi wetu wa kitaalamu wanaweza kutoa huduma za usakinishaji wa mlango kwa mlango, msaada wa kiufundi, na mafunzo ya uendeshaji kwa wateja wa mistari ya usindikaji.

- Hög effektivitet och låg energiförbrukning. Helt automatiserad drift för snabb och effektiv bearbetning. Endast en liten mängd arbetskraft krävs för att slutföra hela processen. Samtidigt följer våra maskiner konceptet för energibesparing, vilket minskar energiförbrukningen.

Kostnadsanalys av anläggning för att göra vitlökspulver

The cost of a garlic powder-making plant varies according to machine configuration, output scale, automation degree, brand awareness, after-sales service, and additional machines.

Om du vill ha det specifika priset för vitlökspulverproduktionslinjen kan du skicka oss bearbetningskapaciteten och efterfrågan på maskiner. Vi kommer att utföra en kostnadsanalys för den produktionsskala du behöver.

Ni Nini Kinachopaswa Kuzingatiwa Wakati wa Uzalishaji wa Poda ya Kitunguu Saumu?

Udhibiti wa ubora wa malighafi. Ili kuhakikisha kuwa vitunguu havina mold, ili kuepuka kuathiri ubora wa bidhaa iliyokamilika.

Temperature control. Appropriate temperature control is needed during drying and crushing to avoid high temperatures destroying the active ingredients of garlic.

Cleaning and sanitizing. All food contact machines must be cleaned regularly to avoid cross-contamination.

Maswali Yanayoulizwa Mara kwa Mara

Je, kiwanda cha usindikaji wa unga wa vitunguu kinaunga mkono usindishaji wa vifaa vingine?

Mstari wa uzalishaji wa unga wa vitunguu saumu unaendana na usindikaji wa vifaa vingi vikavu, kama vile unga wa tangawizi, unga wa pilipili, na unga wa kitunguu.

Je, mchakato wa kukausha utaangamiza virutubisho vya vitunguu?

The garlic dryer adopts low-temperature drying technology to maximize the retention of garlic’s nutrients and natural flavor. It also ensures that the moisture content meets food preservation requirements.

Je, gharama za matengenezo za kiwanda cha kutengeneza unga wa vitunguu ni kubwa?

Gharama za matengenezo ni za chini, ambazo hasa zinajumuisha kusafisha vifaa, kubadilisha sehemu zinazov wear (kama vile chujio na visu), na matengenezo ya kawaida.

Wasiliana Nasi!

The best machines aren’t just products sold to you—they’re partners that grow alongside your business. If you’d like professional advice tailored to your specific needs, contact our expert team today. We offer customized solutions.