Упаковочная машина для чесночного порошка — это высокоэффективная, высокоточная автоматизированная система, разработанная специально для гранулированных продуктов, что делает ее идеальной как для небольших и средних производителей продуктов питания, так и для крупных промышленных линий.

Она поддерживает высокую скорость упаковки 30–75 мешков в минуту, с диапазоном наполнения от 5 г до 600 г, и совместима с несколькими стилями мешков, включая мешки с обратной запайкой, трехсторонней запайкой и четырехсторонней запайкой.

Как работает вертикальная упаковка-наполнитель-герметик?

Определение и приложения

Вертикальная упаковочная машина для фасовки и запайки представляет собой упаковочное оборудование с высокой степенью автоматизации. Машина формирует, наполняет и запечатывает рулоны упаковочного материала в вертикальном направлении для формирования конечного упакованного продукта.

Вертикальная фасовочно-упаковочная машина подходит для упаковки порошков в различных отраслях промышленности, таких как пищевая промышленность, производство предметов первой необходимости, химия, сельское хозяйство и так далее. Если вы не уверены, что ваше сырье подходит для оборудования для упаковки порошков, вы можете связаться с нами для получения разумной консультации.

Множество преимуществ

- Высокая степень автоматизации. Вертикальная упаковочная машина с фасовкой и запечатыванием снижает трудоемкость ручного труда и в то же время повышает эффективность производства и стабильность качества продукции.

- Высокая точность и стабильность. Оборудование для упаковки порошков оснащено двухпроцессорной микрокомпьютерной системой управления и высокоточными шаговыми двигателями, которые обеспечивают точное дозирование, надежную запайку и точную разрезку каждого пакета.

- Универсальность. Поддержка производства множества различных материалов и различных типов сумок, гибкая для удовлетворения потребностей рынка и клиентов в различных аспектах.

- Интеллектуальное управление с помощью сенсорного экрана. Имеет 5-дюймовый сенсорный ЖК-экран, который может принимать сенсорный входной сигнал и заменять механическую панель кнопок.

- Экономия места. Благодаря вертикальной компоновке и небольшой занимаемой площади он подходит для производственных сред с ограниченным пространством, особенно для производственных линий малого и среднего размера.

- Простота в эксплуатации. При настройке параметров во время упаковки нет необходимости останавливать машину.

- Изготовлен из нержавеющая сталь 340. Он соответствует GMP требованиям и подходит для упаковки пищевых продуктов высокого стандарта.

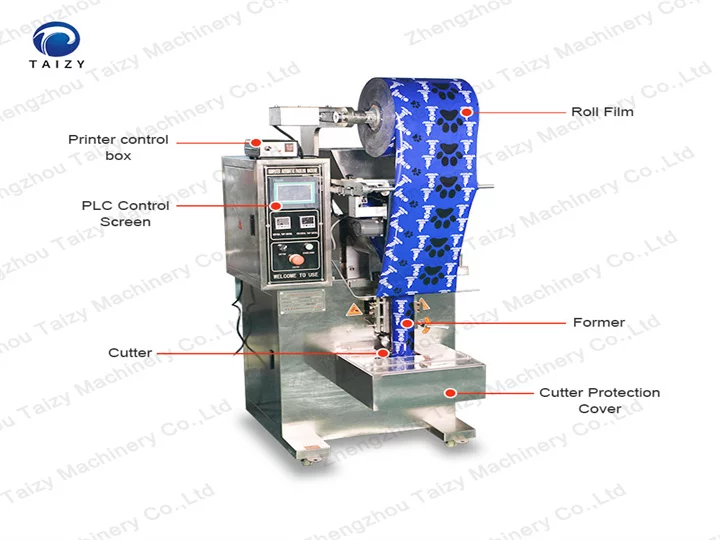

Основные структуры

Система управления

Оснащенная системой управления ПЛК в сочетании с интерфейсом сенсорного экрана, операторам удобно настраивать параметры и контролировать работу оборудования.

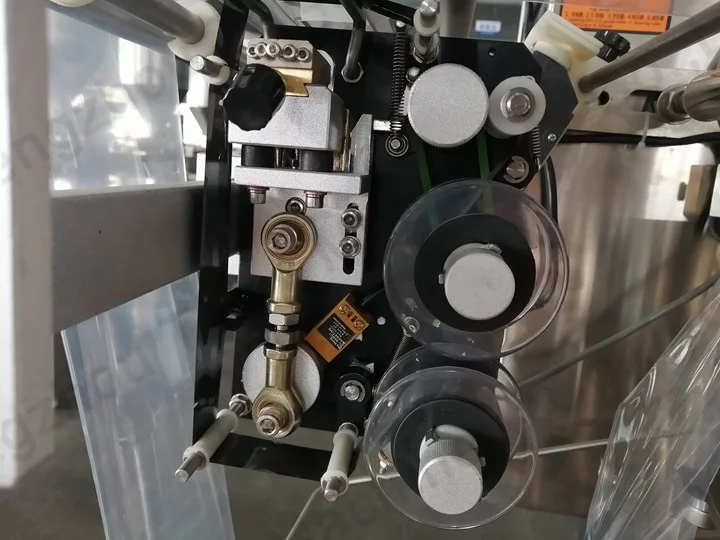

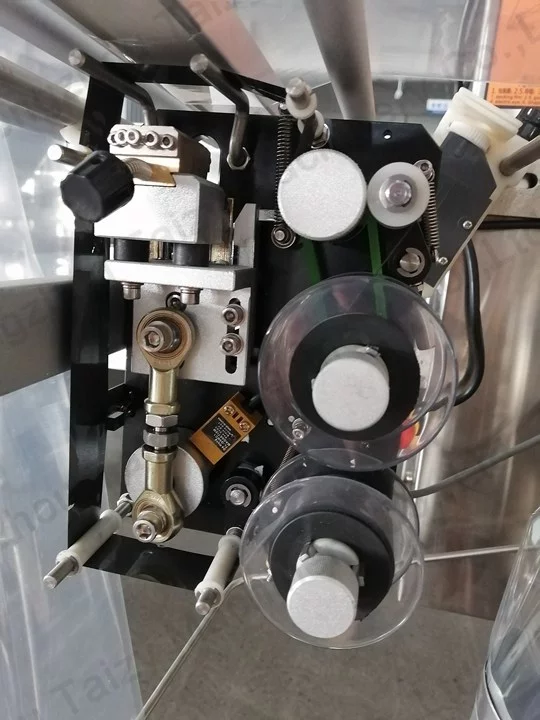

Система изготовления сумок

Включает раму для прокатки пленки, формовочное устройство и устройство для термосваривания. Упаковочный материал подается в формовочное устройство через раму для прокатки пленки, а формовочная машина складывает его в форму пакета и запечатывает горловину пакета с помощью устройства для термосваривания.

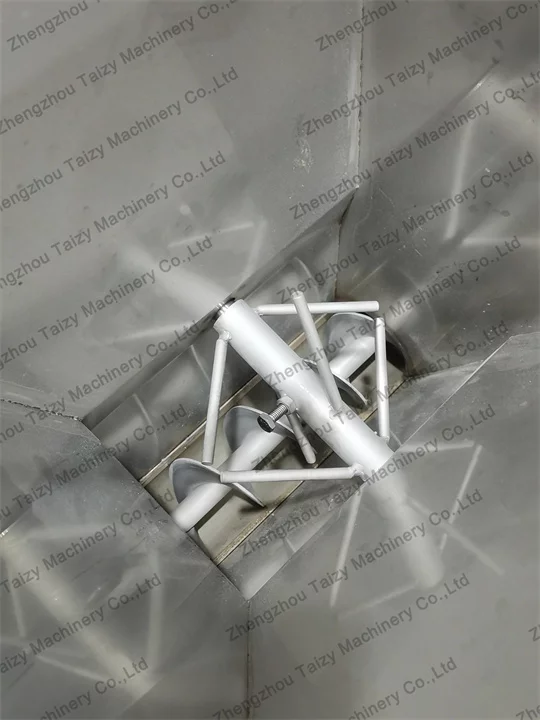

Система дозирования и наполнения

В устройстве дозирования и наполнения упаковочного порошка используется винтовая система наполнения, обеспечивающая постоянный вес каждого мешка.

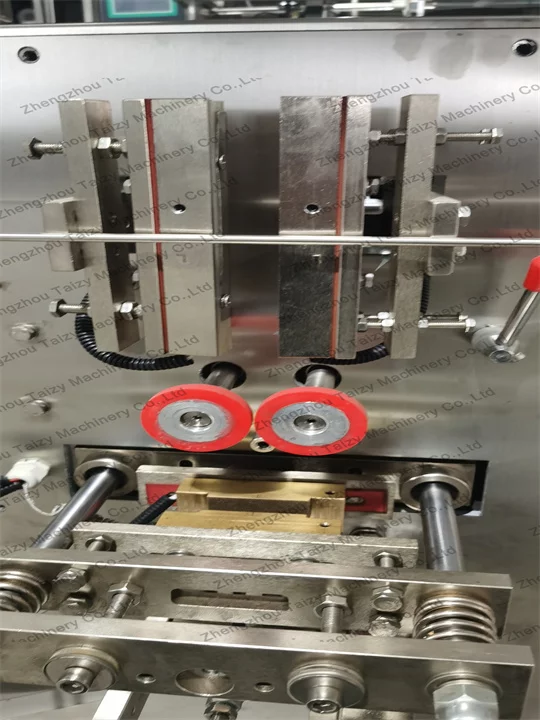

Уплотнительное устройство

Эта часть герметизирует горловину мешка путем нагрева, чтобы обеспечить хорошую герметичность мешка, предотвращая утечку и загрязнение.

Система резки

После запечатывания режущее устройство разрезает пакеты в соответствии с заданной длиной, чтобы каждый готовый пакет был одинакового размера.

Простой и эффективный процесс упаковки

- Подача сырья. Материал подается в систему дозирования вручную или автоматически.

- Формирование сумки. Упаковочную пленку складывают и придают ей форму пакета на формовочной машине, образуя первоначальную структуру пакета.

- Наполнительный материал. Дозирующее устройство точно наполняет мешок материалом в зависимости от типа материала и размера мешка.

- Герметизация. После наполнения открытая часть пакета запечатывается с помощью термосварочного устройства для обеспечения хорошей герметизации.

- Резка и разделение. После закрытия отверстия мешка режущее устройство разрезает пакеты по заданному размеру и разделяет каждый пакет на отдельные готовые изделия.

- Выход готовой продукции. Готовые мешки отправляются на последующие этапы обработки, такие как проверка, упаковка и складирование.

Продажа оборудования для упаковки порошков

| Модель | ТХ-320 |

| Скорость упаковки | 30-75 мешков/мин |

| Длина сумки | 30-180 мм |

| Ширина сумки | 30-150 мм |

| Диапазон заполнения | 1-500мл |

| Потребляемая мощность | 1,2 кВт |

| Масса | 300 кг |

| Размеры | 850*950*1800 мм |

| Запечатывание форм | заднее уплотнение/трехстороннее уплотнение/четырехстороннее уплотнение |

У нас есть много типов и моделей вертикальных упаковочных машин. Если интересно, вы можете отправить нам вес вашей упаковки, сырье, размер упаковки. Мы настроим для вас высококачественные упаковочные автоматы.

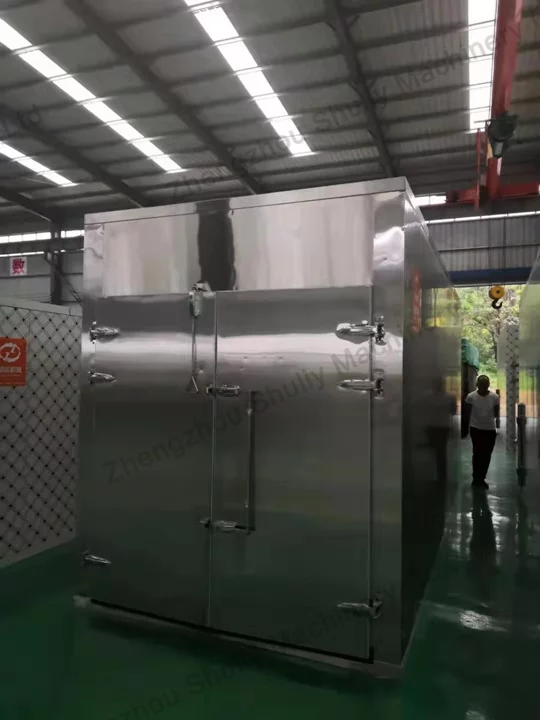

Помимо машины для упаковки чесночного порошка, Taizy Machinery также имеет другое оборудование. Например, машина для нарезки чеснока, сушилка для чеснока, измельчитель чеснока и так далее. Создайте свою линию по производству порошковой упаковки с помощью комплексного обслуживания.

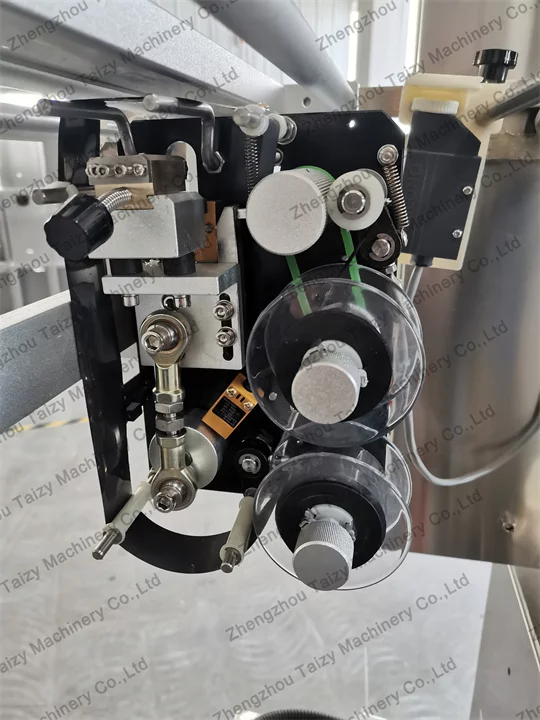

Поддерживает широкий спектр дополнительных функций

Вертикальная упаковочная машина с наполнением и запайкой также может быть оснащена кодировочной машиной, винтовым конвейером, загрузочным бункером, упаковочной пленкой, нижним разгрузочным ножом, пробивкой закругленных углов, легко отрываемым, накачивающим, вытяжным и пылеотсасывающим устройством и другими устройствами. Добро пожаловать на настройку линии по производству упаковки для порошков прямо сейчас!

Методы обслуживания

Смазка

Вертикальную фасовочную и запечатывающую упаковочную машину следует регулярно подвергать ее зубчатому зацеплению, смазочным отверстиям с подшипниками седла и различным подвижным частям, заполненным масляной смазкой, один раз в смену редуктору категорически запрещается работать без масла.

Очистка

После остановки вертикальной упаковочной машины с заполнением и запечатыванием мы должны своевременно очищать измерительную часть и часто очищать корпус термосварщика, чтобы гарантировать, что текстура запечатывания упаковки готового продукта будет чистой. Часто очищайте от пыли электронный блок управления, чтобы предотвратить короткое замыкание, плохой контакт и другие электрические неисправности.

Работы по техническому обслуживанию

При использовании машины для упаковки порошков для проверки частей винтов не должно быть люфтов, в противном случае это повлияет на нормальное вращение машины. Для его электрических частей следует обратить внимание на водонепроницаемость, влагозащищенность, антикоррозийность, антигрызунную работу.

Часто задаваемые вопросы

Какие продукты может упаковывать эта машина?

Чесночный порошок, имбирный порошок, порошок чили, пряностный порошок, мука и другие мелкие порошки.

Какой тип упаковки она поддерживает?

Мешки с обратной запайкой, мешки с трехсторонней запайкой, мешки с четырехсторонней запайкой или саше — в зависимости от модели.

Какова скорость упаковки?

Обычно 30–75 мешков/мин, в зависимости от размера и материала мешка.

Может ли она работать с принтером дат?

Да. Принтер дат, азотная заправка и пылесос — по желанию.

Какую послепродажную поддержку предоставляют?

Онлайн-инструкции по установке, обучение работе, запасные части и долгосрочное техническое обслуживание.

Свяжитесь с нами для получения последней цены!

Если вы планируете войти в индустрию обработки чесночного порошка, инвестиции в современную упаковочную машину для чесночного порошка — ваш лучший первый шаг к успеху.

Свяжитесь с нами сегодня для получения подробных цен и индивидуальных решений по упаковке, чтобы уверенно развивать ваш бизнес в сфере продуктов питания.