ガーリックペースト製造機は、効率的な切断技術により、ニンニクを細かいニンニクピューレに迅速に加工することができ、ケータリング業界、食品加工工場、さまざまな食堂で広く使用されています。ガーリックペーストマシンは生産効率を高めるだけでなく、ガーリックピューレの品質と味を保証し、より均一で繊細なものにします。

ガーリックピューレは何に使われますか?

ガーリックペーストは、一般的な風味付け成分として料理や食品加工に広く使用されています。その主な用途は次のとおりです。

- 料理の調味料。ガーリックピューレは、シチュー、炒め物、スープなどの料理のベース調味料として使用でき、料理に香りと風味を加えます。

- 調味料。ガーリックペーストは、多くのソースや調味料の主成分です(例: ガーリックソース、ガーリックチリソース、ガーリック醤油など)があり、外食産業で広く使用されています。

- 材料をマリネします。ガーリックペーストは、塩漬け肉、塩漬け魚、野菜のピクルスなどの食品をマリネするために他のスパイスと一緒によく使用され、食材の風味を高めることができます。

- ヘルスケア機能。ガーリックペーストは、抗酸化物質や免疫力の強化などの役割を果たすために、伝統的な薬膳料理やヘルスケア製品によく使用されています。

- すぐに食べられる商品。ガーリックペーストは、サラダ、サンドイッチ、ピザ、その他の食品に加えるなど、すぐに食べるのに適した、すぐに食べられる製品として販売することもできます。

ガーリックペーストマシンの設備のユニークさ

- 高いパフォーマンス。 ガーリックペースト製造機は高度な切断および粉砕技術を採用しており、大量のニンニクを迅速に処理し、手動操作時間を短縮できます。

- 一貫性と均一性。 正確な粉砕システムが装備されているため、ニンニクペーストが細かく均一になり、粒子が粗すぎたり、細かすぎたりすることはありません。

- 幅広い適用性。ジャガイモ、生姜、唐辛子、玉ねぎ、ピーマン、ニンジン、その他の野菜を扱うことができます。バナナ、リンゴ、イチゴ、梨、桃、その他の果物も粉砕できます。

- 高い耐久性。 高品質のステンレス鋼素材を使用しており、耐食性と耐熱性に優れており、長期間使用しても損傷しにくいです。

- 掃除やメンテナンスが簡単です。 みじん切りニンニクマシンの構造設計はシンプルで、部品は分解して掃除が簡単です。使用後の衛生状態を維持し、食品安全基準を満たしています。

- 1人でも操作可能です。 自動化機能が搭載されているので、ユーザーはニンニクを機械に入れるだけで済みます。

カスタマイズ可能なコンポーネント

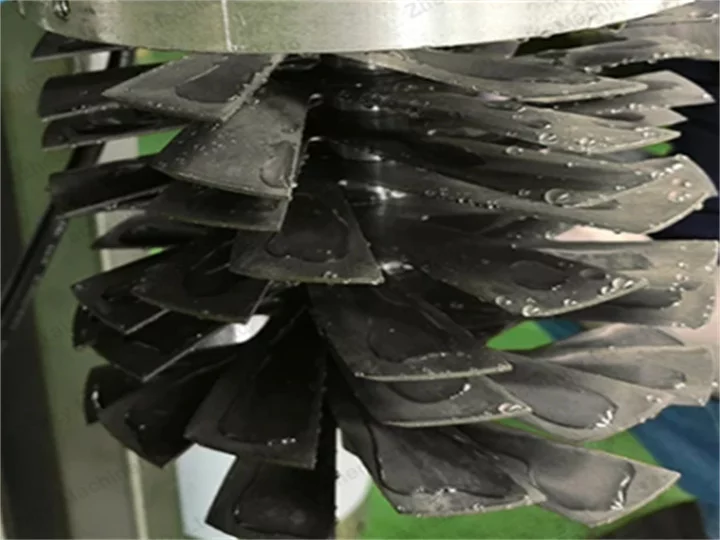

まずは刃の枚数。必要なガーリックペーストの細かさに応じて、刃の数を増減できます。刃の数が増えるほど、粒子は小さく、より細かくなります。

2つ目はモーターパワーです。さまざまな生産規模と処理能力に応じて、ガーリックペースト製造機のモーター出力をカスタマイズして、さまざまな負荷条件下での機械の安定性を確保できます。

第三に、放電設計。さまざまな生産ラインやコンテナに適応するために、ガーリックマッシャーマシンの排出設計をカスタマイズして、お客様がその後の生産プロセスに容易にアクセスできるようにすることができます。

販売のためのガーリックペースト製造機

モデル: TZ-800

全体のサイズ: 950*380*1000MM

電気仕様: 380V。 50Hz

出力: 600-800KG/H

電力: 2.2KW

重量: 95KG

オープンフィード開口部サイズ: 300*360MM

地面からの排出高さ: 400MM

このTZ-800モデルの他に、TZ-500、TZ-1000などのモデルもございます。お客様のさまざまな規模の生産ニーズにお応えします。

また、ガーリッククロービング機およびガーリック皮むき機をお客様に選んでいただき、ニンニクの加工効率を向上させることができます。機器についてお気軽にお問い合わせください!

ガーリックペーストマシンの価格

ガーリックペースト製造機の価格は、ブランド、機能、処理能力、カスタマイズのニーズによって異なります。一般に、価格は次のように大別できます。

- 家庭用ガーリックマッシャーマシン: 家庭のキッチンで日常的に使用できる価格は約 100 ドルです。

- 業務用ガーリックグラインダーマシン: レストランや小規模食品加工業に適しており、機能性と耐久性に優れた数千ドルの価格帯です。

- 工業用ガーリックペースト製造機: 食品加工工場や大量生産向けに設計されており、市販のものよりも高価です。

よくある質問

ガーリックマッシャーマシンは材料を加熱しますか?

そうではありません。この機械は主に、複数の刃を互いに当ててニンニクをニンニクピューレに加工するため、食材の鮮度や栄養素が保たれます。

ガーリックペーストマシンの寿命はどのくらいですか?

寿命は機器の品質とメンテナンスの頻度に大きく依存します。 Taizy のニンニクみじん切り機はステンレス鋼素材を使用して製造されており、適切なメンテナンスを行えば 5 ~ 10 年以上使用できます。ブレードやモーターなどの主要コンポーネントを定期的に清掃し、メンテナンスすることで、機械の寿命を延ばすことができます。

どのくらい連続して動作できますか?

ガーリックペースト製造機は、工場の継続的で中断のない作業環境を十分に考慮して設計されており、通常は作業を行うことができ、機械の保護的な役割を果たすために適切な停止の途中で作業することもできます。