With rising labor costs and growing demand for processed garlic in the food industry, more manufacturers are turning to automation. A fully automated Garlic Peeler Line not only boosts efficiency but also ensures product consistency, hygiene, and output capacity.

This article introduces the four key machines essential for building a modern garlic processing line—from initial separation to final packaging.

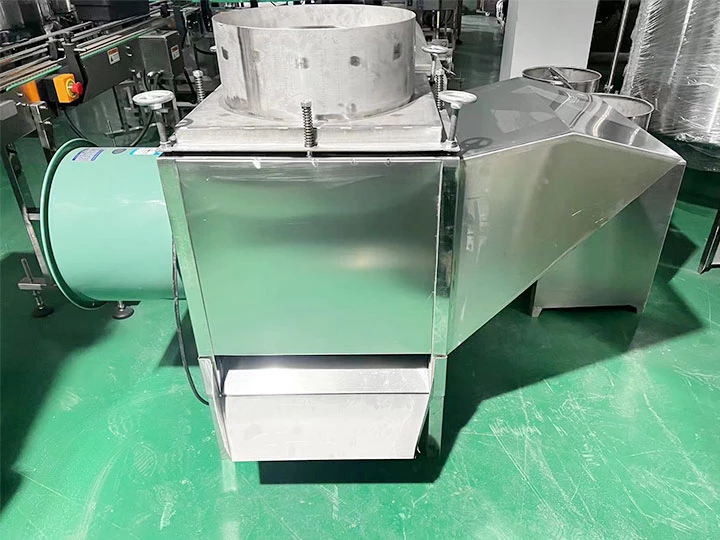

Garlic bulb breaking machine

The garlic bulb breaker is the first step in automation. It separates garlic bulbs into individual cloves without damaging them.

Features:

- Rubber rollers to prevent clove breakage

- Adjustable gaps for different garlic sizes

- High efficiency and labor-saving

Function in the Line: prepares raw garlic for peeling by efficiently separating bulbs.

Garlic peeling machine

A core component of the Garlic Peeling Line, this peeling machine removes the skin from garlic cloves using air compression and friction technology—without water or chemicals.

Advantages:

- No damage to cloves

- Clean, food-grade peeling

- Low noise, easy maintenance

Benefit: greatly reduces manual labor while improving cleanliness and processing speed.

Garlic color sorter

After peeling, the garlic cloves go through a color sorting machine that uses high-speed cameras and AI to detect and reject defective or discolored cloves.

Highlights:

- Accurate defect detection: black spots, mold, skin residue

- Adjustable sensitivity settings

- Maintains product quality and visual appeal

Role: ensures only high-quality garlic passes into packaging.

Vacuum packaging machine

For shelf life and product presentation, a vacuum packing machine is vital. It packs the clean garlic cloves into air-tight bags, preserving freshness and preventing oxidation.

Benefits:

- Long shelf life

- Food-safe sealing

- Supports various bag sizes and materials

Purpose: provides the final touch of automation for commercial garlic distribution.

Conclusion

Building an efficient Garlic Peeling Line requires more than just a peeling machine. From breaking and peeling to sorting and packing, these four machines work together to create a seamless, high-capacity garlic processing system that meets modern food industry standards.

Welcome to contact us for customized solutions, quotation details, and on-site trial videos.