En la industria de procesamiento y envasado de polvo de cebolla, las máquinas de envasado de polvo de cebolla se han convertido en una pieza de equipo indispensable. Este artículo le guiará a través de los principios de funcionamiento, la estructura central y las ventajas de las máquinas de envasado de polvo de cebolla.

¿Por qué es necesaria una máquina de envasado de polvo?

Para la mayoría de plantas de procesamiento de alimentos o fabricantes de condimentos, la etapa de envasado a menudo determina directamente la competitividad en el mercado y los márgenes de beneficio. Las preocupaciones clave de los clientes incluyen:

¿La precisión del envasado es constante?

¿Puede garantizar un peso uniforme por paquete a pesar de las distintas densidades de polvo?

¿Puede igualar la velocidad de la línea de producción?

¿Permite un envasado continuo a alta velocidad que se integre sin problemas con los pulverizadores y transportadores aguas arriba?

¿Es cómodo la limpieza y el mantenimiento?

¿Se atasca fácilmente el polvo? ¿Es fácil de limpiar al cambiar de materias primas?

¿La máquina admite envasado de múltiples especificaciones?

¿Puede ajustar flexiblemente los tipos de bolsas y los pesos de envasado para satisfacer las diferentes necesidades de los clientes?

Principio de funcionamiento de la máquina de envasado de polvo de cebolla

Máquinas de envasado de polvo normalmente consisten en los siguientes sistemas principales:

- Sistema de alimentación

Transfiere automáticamente el polvo desde el tolva al dispositivo de dosificado, comúnmente vía alimentación por tornillo o alimentación por vacío.

Ventajas: elimina el contacto manual, mantiene la higiene ambiental.

- Sistema de medición

El componente central es el dispositivo de dosificado de tornillo. Al ajustar la velocidad de rotación y las revoluciones, controla el peso del polvo dispensado por ciclo.

Principio: la tornillo giratorio descarga cuantitativamente el polvo, adecuado para diversos polvos de flujo deficiente.

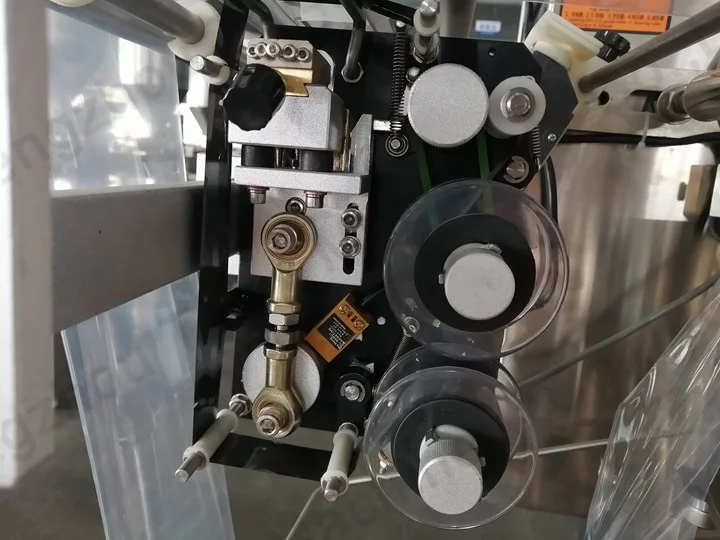

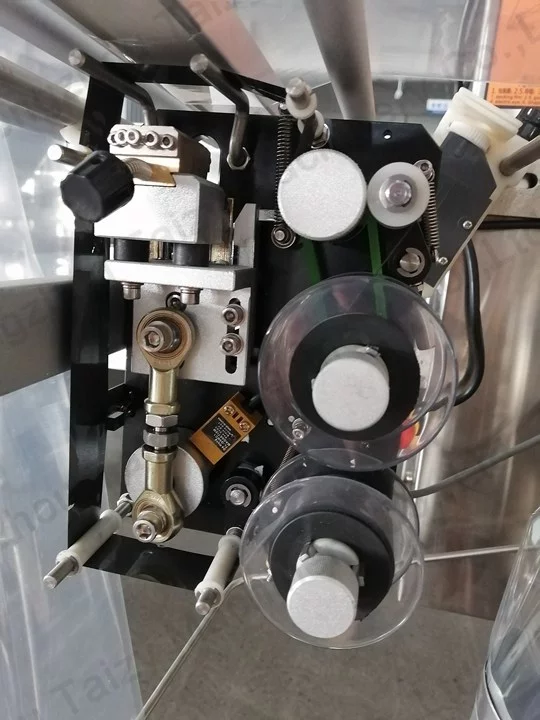

- Sistema de formación de bolsas

La película (p. ej., PET/PE, OPP/CPP) se alimenta a través de un dispositivo de tracción hacia la unidad de conformado, donde se dobla y sella automáticamente para formar una bolsa.

Puede producir bolsas de almohadilla, bolsas planas o bolsas con pliegues según lo requerido.

- Sistema de llenado y sellado

El polvo se dosifica en las bolsas a través de la boca de descarga y, al mismo tiempo, se realiza el sellado térmico para garantizar estanqueidad y resistencia a la humedad.

- Impresión y salida del producto terminado

Las impresoras de inyección de tinta integradas aplican fechas de producción y números de lote. Los productos terminados se descargan automáticamente o se trasladan a la etapa de envasado.

Ventajas de la máquina envasadora de polvo Taizy

Aprovechando años de experiencia en la fabricación de maquinaria para procesamiento de alimentos, nuestra máquina de envasado de polvo totalmente automática está diseñada específicamente para empresas alimentarias medianas o grandes y fábricas exportadoras, equilibrando alta eficiencia con precisión. A continuación se presentan las ventajas clave que más valoran nuestros clientes:

Sistema de dosificación de precisión

Utilizando tecnología de dosificado por servo tornillo, cada paquete mantiene un margen de error dentro de ±0,2 g, asegurando la consistencia del producto y minimizando el desperdicio de materia prima.

Sistema de control inteligente

Equipada con PLC + pantalla táctil para operación intuitiva, permitiendo cambios rápidos entre especificaciones de envasado, interfaces en diferentes idiomas y tipos de bolsa. Soporta visualización bilingüe chino-inglés.

Compatibilidad con múltiples materiales en polvo

Apto para:

- Polvo de cebolla, polvo de jengibre, polvo de ajo, polvo de chile

- Polvo de café, polvo de proteína, polvo de leche

- Polvo de pesticidas, detergente, polvos químicos, etc.

Una máquina sirve para múltiples propósitos, ayudando a los clientes a ampliar sus líneas de productos.

Diseño higiénico y seguro

Todas las piezas en contacto con el material son de acero inoxidable 304, que permite un desmontaje y limpieza rápidos. Cumple con normas de grado alimentario para evitar contaminación cruzada.

Integración sin costuras con líneas de producción completas

Puede combinarse con trituradoras, alimentadores, clasificadores, selladores, etc., para formar líneas de envasado automático de polvo, aumentando significativamente la eficiencia de producción.

Instalación global y soporte técnico

Nuestros centros de servicio colaborativos en Asia, África y Europa proporcionan instalación, puesta en marcha, formación de operadores y soporte posventa, asegurando una compra sin preocupaciones y operación sin complicaciones.

Conclusión

En el ferozmente competitivo mercado de procesamiento de polvo de cebolla, una máquina de envasado de polvo de cebolla de alto rendimiento se traduce en mayor capacidad de producción, menor coste y calidad más constante.

Si buscas una solución de envasado automatizada, rentable y personalizable, contacta a nuestro equipo de ingeniería para una propuesta y cotización gratuitas.