La máquina trituradora de jengibre automatizada no solo es capaz de triturar una amplia gama de materiales hasta 1000 kg/h con alta eficiencia, sino que también es capaz de personalizar la cantidad de cuchillas, el tamaño de la abertura de alimentación, etc. Además de esta máquina trituradora de jengibre, también contamos con exprimidor de jengibre, lavadora de jengibre y otros equipos para respaldar la configuración de la línea de producción.

Características de la máquina trituradora de jengibre

Alta eficiencia. La máquina para hacer pasta de jengibre puede realizar la alimentación y descarga simultáneas, mejorando enormemente la eficiencia del procesamiento de alimentos.

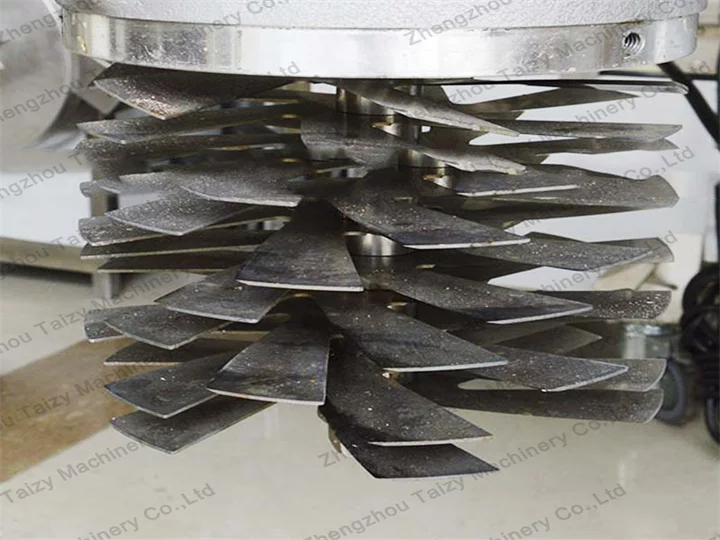

Excelente aplicabilidad. Puede triturar todo tipo de frutas y verduras en pasta, y se puede ajustar el número de cuchillas para controlar el tamaño y la coarseza de la trituración.

Acero inoxidable. Está fabricado en acero inoxidable 304, por lo que es resistente al desgaste, duradero y fácil de limpiar.

Duradero. El ruido generado durante el procesamiento es bajo y la tasa de fallos es extremadamente baja.

Fácil de mover. Pequeño volumen. Es adecuado para restaurantes, plantas de procesamiento de frutas y verduras, hoteles, comedores y otros campos.

Abertura de alimentación ampliada y ensanchada. Es conveniente para la alimentación y produce un mayor rendimiento.

¿Puede la máquina para hacer pasta de jengibre procesar otros ingredientes?

Además del jengibre, las máquinas trituradoras de jengibre a menudo pueden procesar ajo, cebolla, pimientos y una serie de otras verduras de textura más blanda, procesándolas en puré.

Principio de funcionamiento de la máquina de puré de jengibre

La máquina trituradora de jengibre se utiliza principalmente para romper rápidamente el jengibre en gránulos o lodo mediante la rotación de alta velocidad de cuchillas compuestas con múltiples juegos de cuchillas. Los clientes pueden decidir el grado de rotura según la velocidad de colocación de los materiales y el número de cuchillas.

¿Cómo triturar jengibre fresco para obtener pasta de jengibre?

- preparar los ingredientes: limpiar el jengibre y quitar la tierra superficial y las impurezas. Si es necesario, pela el jengibre para asegurar la textura y el color del puré de jengibre.

- Iniciando la unidad: conecte la fuente de alimentación y encienda y apague la unidad. Nuestro molinillo tiene sólo dos botones para el interruptor de encendido/apagado, lo que facilita su funcionamiento.

- soltar jengibre: coloque el jengibre preparado en la abertura de alimentación de la máquina trituradora de jengibre.

- Aplastante: la cuchilla giratoria de alta velocidad corta rápidamente el jengibre en trozos pequeños hasta triturarlo hasta alcanzar el tamaño de partícula requerido.

- Recogiendo el puré de jengibre: el puré de jengibre procesado sale del puerto de descarga y el usuario puede utilizar un recipiente para recibir el puré de jengibre.

- Limpieza y mantenimiento de equipos.: después de su uso, apague la alimentación y comience a limpiar el equipo.

¿Es necesario reemplazar las cuchillas con frecuencia?

La frecuencia de reemplazo de las cuchillas depende de la frecuencia de uso y de la dureza de los ingredientes que se procesan.

Para el uso diario, las cuchillas suelen durar un año o más, pero es posible que sea necesario reemplazarlas cada 6 a 12 meses si la unidad se utiliza durante largos períodos de tiempo a diario.

Se recomienda comprobar periódicamente el filo de las cuchillas para garantizar resultados de procesamiento óptimos.

Muchos modelos de máquinas de pasta de jengibre a la venta

Disponemos de muchos modelos de trituradoras de jengibre a la venta por debajo de 1000 kg/h. El equipo es de tamaño pequeño, aunque bastante potente.

Si está interesado en el rendimiento de la máquina, puede contactarnos ahora para obtener el precio más reciente y el servicio de personalización del equipo.

Confíe en Taizy como su fabricante de máquinas trituradoras de jengibre

- Innovación Tecnológica. Nuestra empresa se centra en I+D e innovación de maquinaria de procesamiento de alimentos desde su creación en 2011, brindando soluciones más eficientes y de ahorro de energía para satisfacer la demanda del mercado.

- Servicio personalizado. Podemos personalizar las funciones y especificaciones de la máquina para hacer puré de ajo de acuerdo con los requisitos de la escala de producción y la línea de procesamiento de los clientes.

- Soporte postventa. Brindamos a los clientes una gama completa de servicios posventa, que incluyen instalación y puesta en marcha de equipos, capacitación técnica, mantenimiento de rutina y resolución de problemas, para garantizar el funcionamiento eficiente de los equipos y reducir la tasa de fallas.

- Mercado internacionalizado. Nuestros productos se venden con gran éxito en más de 30 países como Europa, América, Sudeste Asiático, etc., y han obtenido un gran reconocimiento por parte de clientes internacionales.