Taizy egg grading machine classifies eggs into 5 and 7 grades using automatic weighing. The eggs will not be damaged during the egg grading process. We have stainless steel egg grading machines and carbon steel egg grader machines for sale according to different customers’ needs.

This egg grader supports multiple models and is suitable for grading various types of eggs, including chicken eggs, duck eggs, goose eggs, salted eggs, and preserved eggs. The egg grading machine has a production capacity of 2,000–10,000 pieces per hour.

Application Scenario of Egg Sorter Machine

The egg sorter machine is suitable for all sizes of egg processing factories, farms, supermarkets, the catering industry, and other places, widely used in the egg production and food processing industry.

Working Principle of Egg Grading Machine

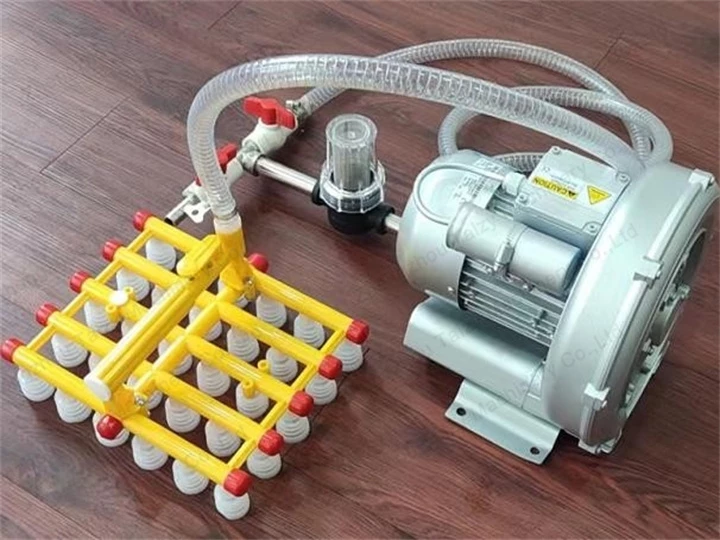

The egg grading process is described below. First, the worker puts the eggs into the front of the egg grading machine using an egg vacuum loading device equipped on the machine. The egg unit can load up to 30 eggs at a time without damaging the eggs.

The egg conveyor then transports the eggs to the egg grading machine for grading. Rubberized rollers on the machine ensure that the eggs move at a constant speed. This effectively causes damage to the eggs.

Subsequently, as the eggs pass through the light inspection area, non-conforming eggs will be detected. At this point, these eggs need to be manually selected. Finally, eggs of different grades come out of different exits.

By the way, the egg grading machine is important in the egg cleaning production line. Users and customers can complete this egg cleaning process by combining the egg washing machine and egg air dryer.

Main Function of the Egg Grader Machine

- An egg suction device can help you load eggs quickly, thereby improving the efficiency of egg grading.

- This machine can accurately divide the eggs into different grades according to the set parameters.

- The sorting machine adopts automation technology, which can automatically complete the operations of weighing, grading, and classifying eggs.

- The egg grader machine is equipped with an optical detection function that can detect eggs with embryos and cracked eggs.

- The machine can be customized according to the user’s needs, including grading grade, grading accuracy, and other parameters.

- Eggs can also be graded for duck, goose, quail, and many other types.

Different Models of Egg Sorting Machine

Currently, we have 4 different models of egg sorting machines for sale: the models are TZ-3700, TZ-4000, TZ-5000, TZ-5400, and TZ-10000. The corresponding production capacities are 3700pcs/h, 4000pcs/h, 5000pcs/h, 5400pcs/h, and 10000pcs/h. This means that no matter whether you want a large egg grading machine or a small egg sorting machine, our machines can meet your needs. Below are the parameters of the different models of egg sorters.

Egg Grader Machine Parameters

| Model | TZ-3700 | TZ-4000 | TZ-5400 |

| Capacity(pcs/h) | 3700 | 4000 | 5400 |

| Power | 5 | 7 | 5 |

| Size(mm) | 1400x1600x1000mm | 1700x1450x1000 | 1800x1600x1000 |

| Grades | 7 | 7 | 5 |

| Voltage(v) | 220 | 220 | 220 |

With the above parameter table, you can know the output, power, size, voltage, and other information of the egg grading machine. The output of an egg grading machine is determined by the number of rows to be graded. The machine with more rows of egg feed has a higher output.

Egg Grading Machine Price

The price of an Egg grader machine can vary based on several factors, such as the brand, model, capacity, and additional features.

Typically, stainless steel Egg grader machines tend to be priced higher due to their durability and hygienic properties, while carbon steel options may offer a more budget-friendly choice without compromising functionality.

In addition, the price of an egg grader machine with light detection is a bit higher than that of a regular egg grader.

It’s crucial to consider not just the initial cost but also long-term maintenance expenses and the machine’s suitability for your specific egg grading needs.

Guides for Choosing the Best Egg Grader Machine

- First of all, you should clarify your needs, including the number of eggs to be graded per day, grading accuracy requirements, budget range, etc.

- According to the demand and budget, choose a suitable model and specification of the egg grader machine. Pay attention to consider the machine’s capacity, grading accuracy, degree of automation, and other factors.

- During the purchase process, pay attention to verifying whether the performance parameters and functions of the machine meet the demand and whether the quality and safety of the product meet the standard.

- When purchasing the egg grader machine, understand the supplier’s after-sales service policy, including warranty period, maintenance methods, parts supply, and other aspects.

The Development Trend of the Egg Grading Machine

With the continuous progress of science and technology, the egg grading machine industry tends to have a higher level of automation and intelligence. Customer demand for intelligent equipment that can improve production efficiency and reduce labor costs is increasing.

At the same time, the market demand for egg grading machines is also becoming more and more diversified, not only a single function of the grading machine, but also with optical detection, data recording, and analysis of a variety of functions, such as all-purpose grading machines.

Customers are also increasing their demand for customized services, as they want to be able to customize their egg grading machines to meet their specific needs.

Taizy Food Machine, as a reputable machine manufacturer in China, can fulfill the above-mentioned needs of our customers with our egg grading machines.

Egg Grader Machine Successfully Exported to Austria

An intelligent TZ-5400 egg sorting machine from Taizy Machinery has completed production, testing, and packaging and has officially departed for Austria. The machine solves the problem of standardisation, which is difficult for farmers to ensure in manual operations, and at the same time, greatly improves production efficiency.

Related Machines

Our egg washing machine is currently selling well. When paired with our egg grading machines, they will significantly enhance the automation and efficiency of your production line.

We also offer fully automated,high-efficiency egg processing lines, including egg washing and drying machines, egg grading machines, egg tray loading machines, and egg coding machines.

These systems enable a continuous processing flow—cleaning → drying → light exposure → grading → coding → packaging—thereby significantly boosting production efficiency. If you’re interested, contact us today for more details.

FAQ

What is the capacity range?

3,700–5,400 eggs/hour, depending on the model.

How many weight grades can it classify?

Typically 4–7 grades, customizable based on your market standard.

What types of eggs can it handle?

Chicken eggs, duck eggs, and similar-sized poultry eggs.

Is the classifier equipped with optical inspection functionality?

Yes. The integrated light inspection function can detect eggs containing embryos and broken eggs.

How many workers are needed?

Only 1–2 operators are needed due to its automated design.

Do you provide installation and after-sales support?

Yes. We offer setup guidance, operation training, spare parts, and long-term technical support.

Egg Grading Machine for Sale

If you need to know more about our egg grading machine, customer cases, or export supporting services, please feel free to contact us for technical information and quotation suggestions.