The egg loading machine, also known as an egg tray loader, is a highly efficient device designed to automatically arrange and load eggs onto trays in a neat and organized manner. This machine is ideal for egg processing plants, poultry farms, and food factories, ensuring gentle handling of eggs to prevent breakage while improving productivity.

With its compact design and customizable configurations, the egg loading machine can handle up to 15,000 eggs per hour, making it a vital tool for large-scale egg production operations.

Application Scenarios of the Egg Loader

The egg loading machine is widely used in:

- Egg processing plants: for sorting and loading eggs onto trays for transportation or further processing.

- Poultry farms: for efficient egg handling and packaging.

- Food factories: for integrating into production lines involving egg-based products.

- Supermarket supply chain stations: for streamlining manual egg handling processes.

Advantages of Our Egg Loading Machine

High efficiency: capable of handling up to 15,000 eggs per hour.

Gentle handling: designed to minimize egg breakage during loading, ensuring high product quality.

Customizable configurations: adjustable tray sizes, loading speed.

Easy maintenance: modular components for convenient repairs and upgrades.

Easy operation: simple control panel for quick setup and operation by a single worker.

Hygienic and safe: made with food-grade materials, 304 stainless steel structure, ensuring cleanliness and safety during operation.

Supports multiple tray types: works with 10, 12, 15, and 30-egg trays, made of paper or plastic.

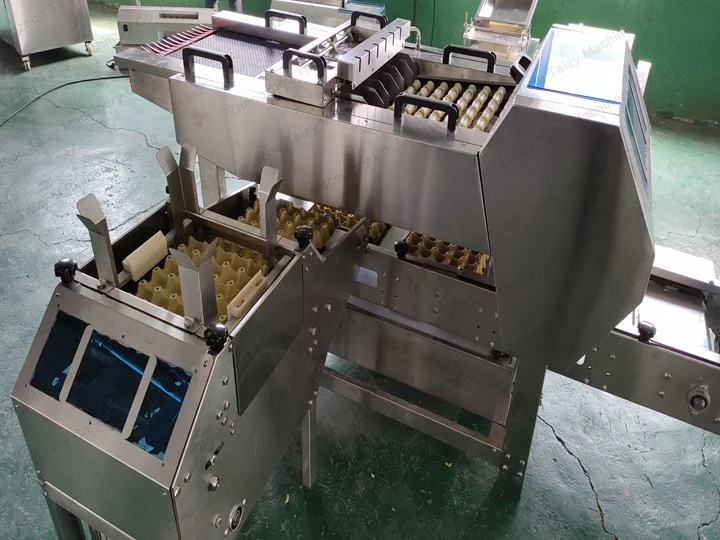

Components of the Egg Planting System

Automatic tray feeder

Automatically feeds multiple empty egg trays into the system. Operators can load up to 50 trays at a time, saving significant manual effort.

| Item | Value |

|---|---|

| Dimensions | 960 × 448 × 850 mm |

| Capacity | 50 trays per batch |

| Voltage | 380v |

| Power | 0.36 kw |

Egg Loading and Orientation Unit

This is the core module of the system. It automatically aligns eggs by size and orientation, then places them gently into the trays with small-end-down positioning. Features include an LCD touchscreen, modular electrical connectors, and stainless steel construction.

| Item | Value |

|---|---|

| Dimensions | 2022 × 770 × 980 mm |

| Capacity | 1,000–15,000 eggs/hour |

| Voltage | 380v |

| Power | 0.36 kw |

Conveyor Output System

Transfers filled egg trays out of the machine automatically for collection or stacking.

| Item | Value |

|---|---|

| Dimensions | 2200 × 410 × 665 mm |

| Capacity | 5,000–7,000 eggs/hour |

| Voltage | 380v |

| Power | 0.18 kw |

Working Video of the Egg Loading Machine

To see the egg loader in action, watch our demonstration video here:

Customizable Production Lines

Our egg loading machine can be integrated into a complete production line, including:

- Egg grader: used to grade eggs by size and quality before loading.

- Egg washing machine: used to wash eggs before packing.

- Egg coding machine: for coding eggs after loading.

Frequently Asked Questions

Can the machine handle different tray sizes?

Yes, the tray loading mechanism is adjustable to accommodate various tray sizes.

Can this machine load eggs into plastic trays?

Yes, it works with both plastic and paper trays of various sizes.

Does the machine guarantee small-end-down orientation?

Yes. It includes automatic size and orientation adjustment to ensure correct positioning.

Can this machine be integrated into a grading or washing line?

Absolutely. The system is modular and designed for seamless integration.

Can the machine layout be turned or curved?

No, this model operates in a straight-line layout and does not support turning.

Request a Quote

Looking to improve egg packaging speed and consistency in your facility?

Contact us now for a quotation, technical support, or demo video.