Como é que o pó de alho finamente moído é embalado de forma organizada em sacos uniformes e herméticos em apenas alguns segundos? O segredo está na máquina de embalagem de pó de alho — uma máquina de embalagem de pó totalmente automatizada, projetada para lidar com tudo, desde a pesagem precisa até à vedação exata.

Neste artigo, levaremos você ao interior do processo automatizado e explicaremos como cada componente contribui para uma embalagem eficiente, higiénica e consistente.

Passo 1: Alimentação e Medição Automática de Material

O processo começa com a alimentação automática, onde o pó de alho é transferido de um funil de armazenamento para a máquina.

- Um sistema de enchimento com parafuso ou espiral mede precisamente a quantidade de pó a embalar. Isto garante:

- Peso consistente do saco, minimizando o desperdício de material.

- Dosagem precisa, mesmo para pós leves ou finos.

Modelos avançados usam sensores fotoelétricos e sistemas de controlo PLC para ajustar automaticamente a velocidade e a precisão — ideal para produção em grande escala.

Passo 2: Formação do Saco

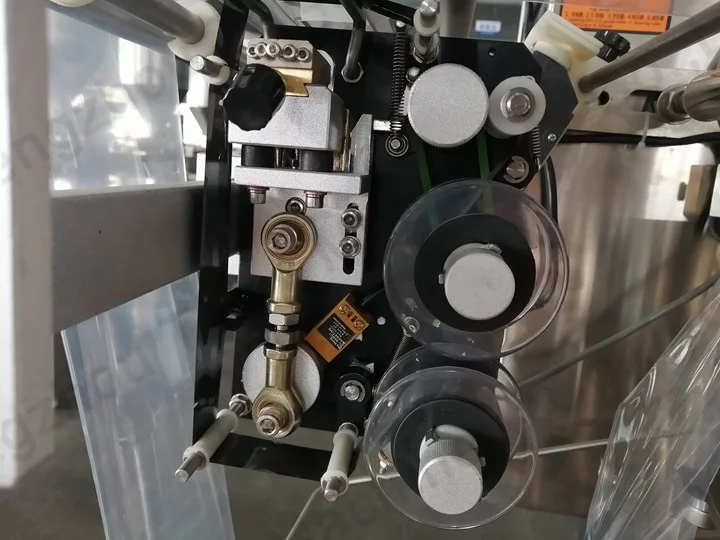

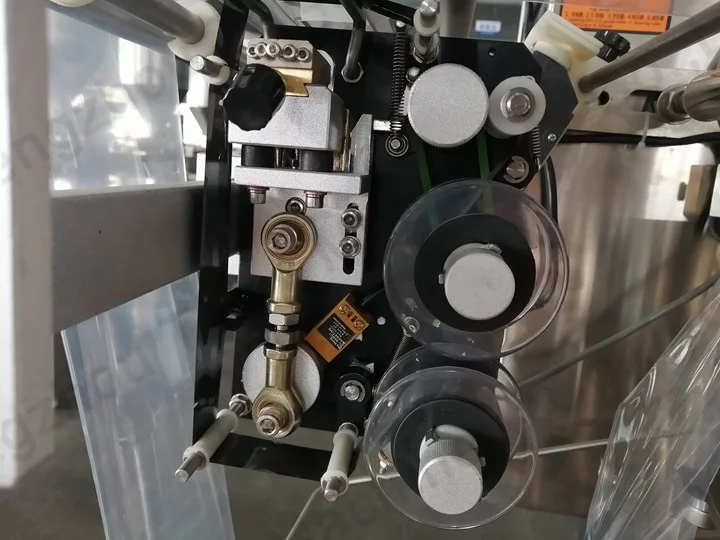

Depois de medir o pó, entra em ação o sistema de formação do saco. A máquina molda automaticamente a película de embalagem (feita de materiais como OPP, PE ou folha de alumínio) em sacos.

O colar de formação garante que cada saco seja consistente em tamanho e alinhamento — um fator essencial para uma aparência profissional e uniforme do produto.

Passo 3: Enchimento e Vedação

De seguida, o pó de alho é dispensado com precisão nos sacos formados.

As barras de vedação verticais fecham os lados do saco, enquanto as mandíbulas de vedação horizontais selam o topo e a base usando calor e pressão controlados.

Este passo garante:

- Vedação hermética que protege a frescura do produto.

- Embalagem à prova de fugas, mesmo durante transporte de longa distância.

Algumas máquinas avançadas de embalagem de pó possuem jateamento de nitrogénio para prolongar a vida útil, reduzindo o oxigénio dentro do saco.

Passo 4: Codificação e Corte

Após a vedação, a máquina pode imprimir números de lote, datas de produção ou logótipos diretamente no saco usando uma impressora jato de tinta ou térmica.

Por fim, o mecanismo de corte separa automaticamente cada saco — entregando bolsas perfeitamente acabadas, prontas para venda.

Vantagens da Máquina de Embalagem de Pó de Alho

A nossamáquina de embalagem de pó de alhoé altamente versátil — pode embalar não só pó de alho, mas também vários outros produtos em pó.

- Automação total: desde a alimentação até ao selagem, todo o processo requer apenas um operador.

- Alta precisão: sistemas de pesagem inteligentes garantem perda mínima de material.

- Versatilidade: adequado para alho em pó, cebola em pó, pimenta em pó, farinha, leite em pó e mais.

- Design higiénico: aço inoxidável de grau alimentar garante conformidade com os padrões de segurança.

- Embalagem personalizável: suporta vários tamanhos de saco, materiais e tipos de vedação.

Estas vantagens tornam-na uma parte essencial de qualquer linha de processamento de pó de alho, ajudando as empresas a melhorar a velocidade de produção e a qualidade do produto simultaneamente.

Por que investir numa Máquina de Embalagem de Pó de Alho?

A embalagem manual é lenta, inconsistente e propensa a contaminações. Em contraste, uma máquina automática de embalagem de pó de alho aumenta a eficiência em mais de 300%, reduz os custos laborais e melhora a qualidade da embalagem — tornando-se uma escolha económica para empresas de processamento de alimentos.

Para empresas que pretendem aumentar a produção ou exportar os seus produtos, a automação não é apenas uma atualização — é uma necessidade.

Contacte-nos para uma solução completa de embalagem de pó

Quer produza pó de alho, cebola ou pimenta, as nossas máquinas de embalagem de pó oferecem a precisão, higiene e fiabilidade que o seu negócio necessita.

Contacte-nos hoje para uma cotação gratuita e um plano de embalagem personalizado.