新鮮なニンニクを乾燥ニンニクパウダーに加工できるラインをお探しですか? Taize Food Machinery は、ガーリックパウダー加工工場向けの完全な設備を提供します。生のニンニクから最終的なガーリックパウダーや袋包装までを簡単に実現でき、自動化レベルと生産効率が大幅に向上し、より多くの経済的メリットが生まれます。

クローブから粉末まで、どのようなニンニク加工機械が必要ですか?

生ニンニクの選別・分別

あらゆるニンニクパウダー加工プラントの最初のステップは、農場から生のニンニクを受け取ることです。ここでは品質管理が重要です。なぜなら、加工に適しているのは新鮮で健全なニンニクのクローブだけだからです。次に、ニンニクカラー選別機を使用して、損傷または腐敗したクローブを除去することで、品質の良いニンニクを確保できます。その後、ニンニク分離機でニンニクを分離する必要があります。

ピーリングと洗浄

ニンニクが選別されたら、皮むきと洗浄の段階に進みます。皮むき機を使用してニンニクのクローブの皮をむき、汚れや破片を徹底的に洗い流します。このステップにより、さらなる加工の前にニンニクが新品同様の状態に保たれます。

スライスと乾燥

洗浄されたニンニクのクローブは、ニンニクスライサーによって薄切りにされます。スライスすることで表面積が増加し、乾燥プロセスがより効率的になります。スライスの後、ニンニクはニンニク乾燥機に移され、ニンニクからすべての水分が除去され、腐敗を防ぎます。

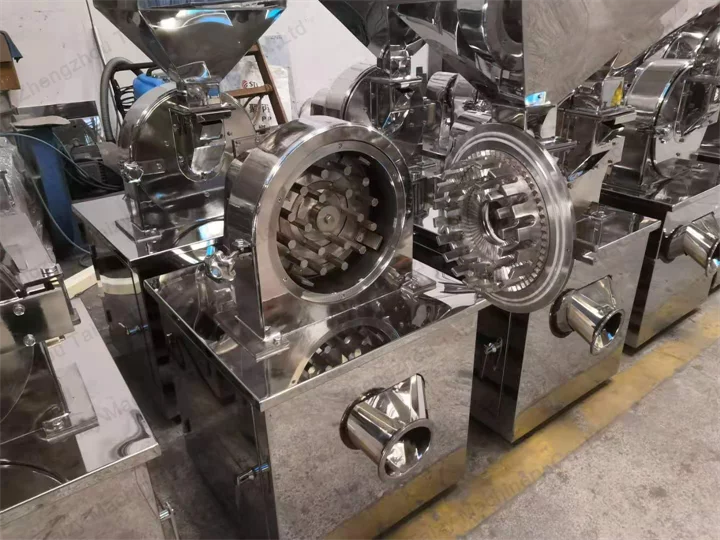

粉砕して粉末にする

乾燥したニンニクフレークは、工業用粉砕機を使用して細かい粉末に粉砕されます。希望するテクスチャーに応じて、粉末はさまざまな細かさに粉砕できます。

品質基準を満たす一貫した製品を製造したい場合は、ガーリックパウダーをふるいにかけ、粒子サイズを均一にすることができます。

包装

ニンニクパウダーを販売用に包装したい場合。その後、ニンニクパウダーは自動粉末包装機によって気密バッグに詰められ、鮮度を保ち、湿気を防ぎます。

ガーリックパウダーマシンメーカー

- 良い評判と市場の評判。食品機械の研究開発および生産における 13 年の経験。世界30以上の国と地域で数多くの成功事例を蓄積しており、お客様からの信頼は高いです。

- カスタマイズされた加工ライン。 当社は、あらゆる規模のお客様のニーズを満たすことができるように、幅広い種類のニンニク加工機を提供しています。また、お客様の個別の要件と予算に応じて機器をカスタマイズすることができます。

- 高い効率とスピード。 ニンニク加工機の自動機械は高生産量を保証し、必要なニンニク製品を迅速に処理します。

- 一貫した品質。 当社の装置は標準化された生産プロセスを使用して、各機械が厳格な品質基準を満たしていることを保証します。設備は安定していて頑丈です。

- 保存期間の延長。 ニンニクから水分を除去することで、ガーリックパウダーの保存期間が長くなり、食品廃棄物が減り、消費者にとって使いやすくなります。

持続可能性と環境への配慮

循環経済の発展に伴い、現代のガーリックパウダー加工工場の多くは持続可能性にも重点を置いています。これらの工場は、廃棄物を最小限に抑え、エネルギー効率の高い機械を使用することで、環境への影響を削減することを目指しています。一部の植物では、ニンニクの皮や根などの加工副産物を堆肥や動物飼料としてリサイクルしています。

サービスとコンサルティング

当社のニンニクパウダー加工プラントには、ニンニク、ジャガイモ、ショウガ、タマネギの加工に適した機械だけでなく、ジューサー装置や卵加工装置も備わっています。

ご興味がおありでしたら、お気軽にお問い合わせいただき、生産ラインのカスタマイズ、最新の見積もりを入手し、割引キャンペーンにご参加ください!12時間以内にお返事いたします。