Bawang putih adalah bahan penting di dapur di seluruh dunia, digunakan dalam saus, bumbu, makanan beku, dan makanan siap saji. Seiring dengan meningkatnya permintaan bawang putih yang sudah dikupas, produsen makanan beralih ke solusi otomatis. Jalur mesin pengupas bawang putih menyederhanakan seluruh proses—dari pemisahan umbi hingga siung yang dikemas vakum—menjamin efisiensi, kebersihan, dan konsistensi.

Dalam panduan ini, kami akan menjelaskan komponen, proses kerja, dan keuntungan dari lini produksi pengupas bawang putih yang lengkap.

Apa itu lini produksi pengupasan bawang putih?

Sistem mesin pengupas bawang putih adalah sistem terintegrasi yang mengotomatiskan pengolahan bawang putih segar menjadi siung yang sudah dikupas, bersih, dan siap dikemas. Ini biasanya mencakup:

Mesin pemisah bawang putih – memecah siung bawang putih utuh menjadi siung individu.

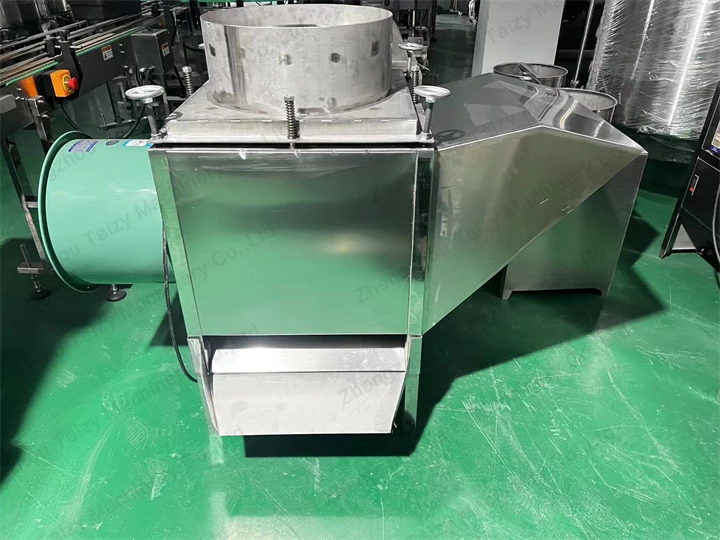

Mesin pengupas bawang putih – menggunakan metode pneumatik atau kering untuk menghilangkan kulit.

Mesin penyortir warna bawang putih – mendeteksi dan menghapus siung yang berubah warna atau cacat.

Mesin pengemas vakum bawang putih – memperpanjang umur simpan dengan kemasan higienis yang tersegel.

Rangkaian produksi ini ideal untuk pengolah bawang putih, pabrik makanan, produsen rempah-rempah, dan pemasok ekspor.

Alur kerja lini pengolahan bawang putih

Berikut adalah cara kerja lini mesin pengupas bawang putih yang khas:

- Pemberian makan: umbi bawang putih dimasukkan ke dalam pemisah.

- Pemisahan: siung-siuang terpisah tanpa kerusakan.

- Pengupasan: kulit luar dihilangkan tanpa air atau bahan kimia.

- Penyortiran: mesin pemisah warna menghilangkan siung yang buruk dan kotoran.

- Pengemasan: siung bawang yang bersih dikemas dalam kemasan vakum untuk distribusi.

Seluruh proses ini otomatis dan berkelanjutan, mengurangi kebutuhan tenaga kerja dan meningkatkan kecepatan produksi.

Keuntungan dari lini mesin pengupas bawang putih otomatis

- Penghematan tenaga kerja – menggantikan pengupasan dan penyortiran manual dengan mesin yang efisien.

- Hasil tinggi – mengurangi kehilangan bawang putih dan kerusakan kulit.

- Higienis dan bersih – struktur stainless steel memastikan standar makanan.

- Dapat diskalakan – tersedia dalam berbagai kapasitas untuk memenuhi operasi kecil hingga besar.

- Siap ekspor – produk akhir memenuhi standar kualitas internasional.

Aplikasi di seluruh industri makanan

Bawang putih yang diproses banyak digunakan dalam:

- Pembuatan rempah dan bumbu

- Produksi makanan beku dan saus

- Campuran sayuran siap masak

- Pengalengan dan pengawetan makanan

- kemasan siung bawang putih ritel

Dengan otomatisasi, bisnis makanan dapat memenuhi pesanan besar sambil menjaga konsistensi dan kualitas.

Mengapa memilih peralatan pengolahan bawang putih Taizy?

Lini produksi pengupasan bawang putih kami dirancang untuk keandalan, daya tahan, dan perawatan yang mudah.

Solusi yang disesuaikan sesuai dengan kebutuhan produksi Anda.

Komponen berkualitas tinggi untuk mesin yang tahan lama dan mudah dirawat.

Video percobaan, demonstrasi kemasan, dan dukungan purna jual.

Layanan satu atap dari tata letak mesin hingga panduan instalasi.

Kesimpulan

Jika Anda ingin meningkatkan efisiensi pengolahan bawang putih Anda, jalur produksi pengupasan bawang putih yang sepenuhnya otomatis adalah investasi jangka panjang terbaik. Ini memastikan produktivitas, kebersihan, dan kualitas produk di pasar makanan yang kompetitif.

Butuh bantuan memilih mesin yang tepat?

Hubungi kami hari ini untuk konsultasi gratis dan solusi yang disesuaikan untuk kebutuhan pengolahan bawang putih Anda.