Ginger grinding machine is a milling machine for grinding ginger, garlic, chili pepper, soybean, corn, sugar, scallion, salt, pepper, anise, fisheye, cinnamon, cloves, wolfberry, ginseng, dried vegetables, and other low and medium hardness materials. The fineness of the finished product can be adjusted between 20-120 mesh by changing the screen. Generally speaking, customers will choose the fineness between 20-40 mesh screens.

Ginger Grinding Machine Working Principle

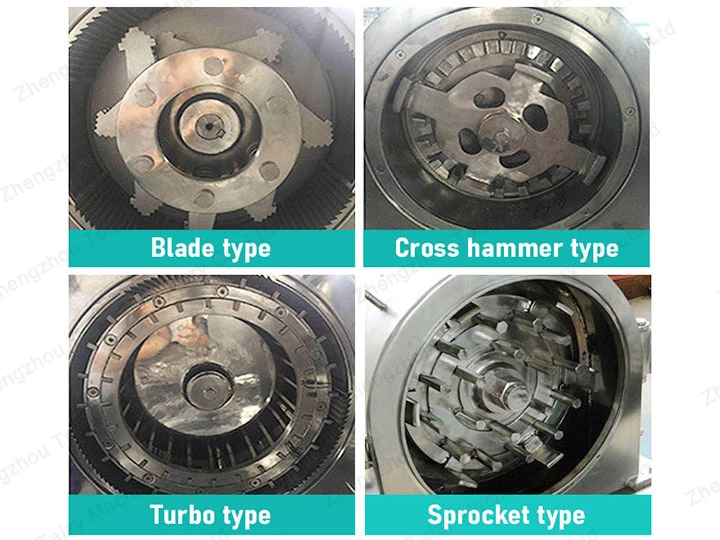

Ginger grinding machine utilizes the relative motion between the high-speed rotating movable tooth plate and fixed tooth plate to crush materials. In the process of ginger crushing, ginger through the tooth plate impact, shear friction, and materials collide with each other to achieve the purpose of crushing materials.

The crushed ginger powder is discharged directly from the crushing room. The particle size of ginger powder can be achieved by choosing different aperture screens.

If you want to get high-quality ginger powder, it is better to use dry ginger slices to make ginger powder. Our company has many models of ginger slicer machines for customers to choose from.

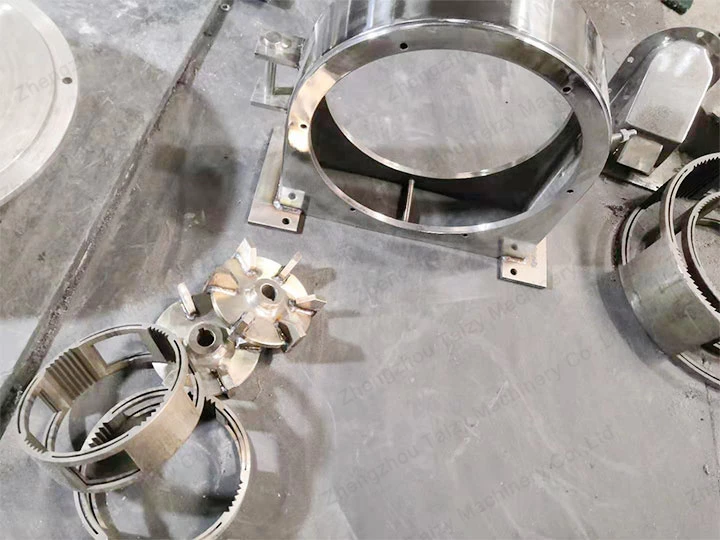

Structure of the Ginger Grinder Machine

The structure of the ginger grinder machine includes an inlet, crushing chamber, outlet, screen, switch, speed control device, loose nut, and so on.

The turbine’s powerful pulverizing bin can help you to get the right mesh size of material. The inlet is designed with rounded edges to prevent cutting hands. Stainless steel outlet can make the material discharged more smoothly and also easy to clean.

Ginger Powder Machine Working Parameters

| Model | 15B | 30B | 40B | 50B | 60B | 80B | 100B |

| Capacity(kg/h) | 20-150 | 80-400 | 100-800 | 150-1000 | 250-1500 | 350-2000 | 500-3000 |

| Feed size (mesh) | <10 | <12 | <15 | <18 | <20 | <25 | <28 |

| Fineness of grinding(mesh) | 20-120 | 20-120 | 20-120 | 20-120 | 20-120 | 20-120 | 20-120 |

| Power(kw) | 2.2 | 7.5 | 11 | 15 | 22 | 30 | 37 |

| Spindle speed(r/min) | 6000 | 3800 | 3400 | 3000 | 2800 | 2400 | 2000 |

| Weight(kg) | 150 | 340 | 450 | 600 | 900 | 1250 | 1580 |

The above are just some of the parameters of the hot-selling ginger powder machine. From the table, you can see that the output of this ginger grinding machine is in the range of 20-3000kg/h. Whether it is a small-scale ginger powder production need or a large-scale milling need, this machine can meet your needs.

Application of Ginger Ginger Powder Making Machine

Ginger powder making machines are suitable for medicine, the chemical industry, food, agriculture grain, and other industries. It is especially suitable for crushing dry and brittle materials. Therefore, ginger grinding machine has a wide range of uses. In the ginger powder production line, this machine is indispensable.

It should be noted that this multifunctional ginger grinding machine may grind dry materials.

Ginger Grinding Machine Advantages

- The whole machine is made of 304 stainless steel.

- By replacing the screen, you can get 20-120 mesh powdery materials.

- Wide range of applications. Suitable for grinding all kinds of dry materials with low to medium hardness.

- The ginger grinding machine has a simple structure, easy to disassemble and maintain.

- The inlet adopts a rounded and smooth edge design to prevent cutting hands.

- Low noise.

How to Choose the Right Ginger Grinding Machine for You?

- Production demand: First of all, you should consider your production demand, including the amount of ginger you need to process per hour and the requirement of crushing granularity.

- Fineness of the finished product. You need to determine the fineness of the finished product you want. This affects the machine screen and knife selection.

- Machine power: Understand the power parameters of the machine to ensure that it can meet your production requirements. Generally speaking, the higher the power, the higher the processing capacity.

- Equipment size: According to the size and layout of the production site, choose the appropriate equipment size. This will ensure that the machine can be installed and run smoothly.

Ginger Grinder Shipping Picture