The complete garlic peeling production line mainly includes a garlic separating machine, a garlic peeling machine, a garlic color sorter, a vacuum packaging machine, and some elevators.

In addition, according to customer needs, we can also be equipped with fruit and vegetable air bubble washing machines, garlic grading machines, garlic slicing machines, garlic drying machines, and other garlic processing equipment for your garlic peeling processing line.

Garlic Peeling Process Working Video

The process of the garlic peeling production line is as follows: lifting, cloving, peeling, color sorting, and packing.

Different Types of Garlic Peeling Production Lines

We can also equip the garlic peeling production line with specific functions of the garlic processor according to the needs of different customers. For example, we can add an air bubble fruit and vegetable washer machine and a garlic slicer machine for customers who want to make garlic chips.

Similarly, we can add a bubble vegetable washing machine, garlic slicing machine, garlic drying machine, garlic grinding machine, and garlic powder packing machine for customers who want to make garlic powder.

Different types of garlic peeling production lines can meet different garlic processing needs. If you are looking for garlic processing equipment, please feel free to contact us.

Key Equipment in Garlic Processing Machine Line

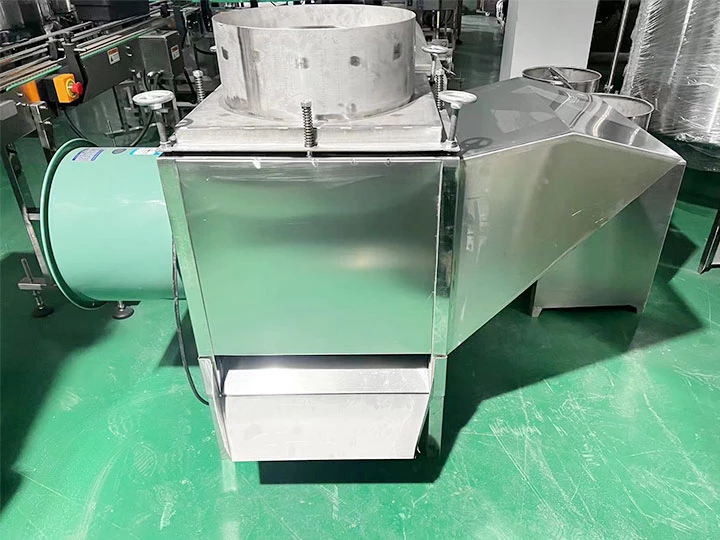

Garlic Splitting Machine

The garlic splitter machine is one of the main machines in the garlic peeling processing line. The garlic splitting machine can divide garlic bulbs into individual cloves. This machine has a 98% cloving rate.

| Model | Voltage(v) | Power(w) | Size(cm) | Weight(kg) | Capacity(kg) |

| TZ-400 | 110-220-380V | 750 | 72*73*115 | 130 | 400 |

| TZ-500 | 110-220-380V | 1500 | 76*73*103 | 120 | 500 |

| TZ-1000 | 110-220-380V | 2200 | 150*70*124 | 150 | 1000 |

Garlic Peeler Machine

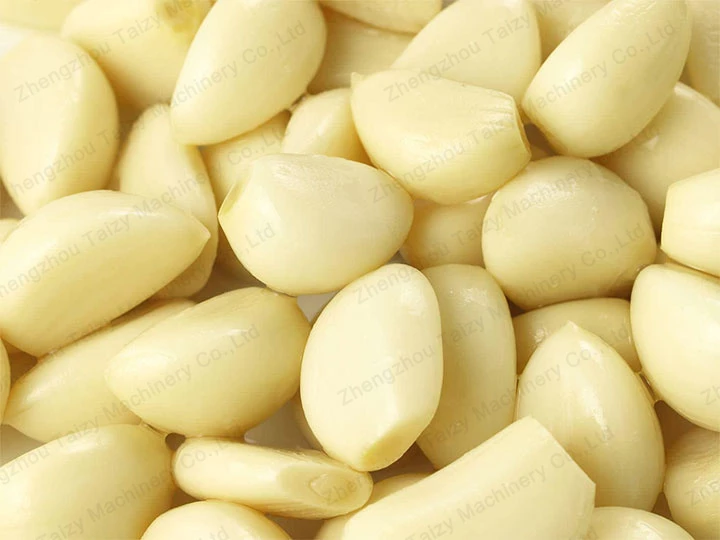

A garlic peeling machine can remove the skin of garlic by utilizing the pneumatic principle. The pneumatic peeling method will not cause damage to the garlic. The peeling rate can reach 98%.

| Model | Capacity(kg/h) | Power(kw) | Voltage(v) | Weight(kg) |

| TZ-G200 | 200 | 1.1 | 110-220-380v | 150 |

| TZ-G600 | 600 | 1.5 | 240v60hz | 350 |

Garlic Color Sorter

A garlic color sorter can sort out the unqualified garlic cloves to improve the quality of garlic.

| Model | TZ-GC800 |

| Capacity | 800kg/h |

| Power | 25000W/220v |

| Wight | 500kg |

| Size | 295x95x180cm |

Vacuum Packaging Machine for Garlic

As the name suggests, a vacuum packaging machine can vacuum-pack garlic to extend the shelf life of garlic. This type of packaging is not only easy to transport and sell, but also very beautiful!

| Model | DZ400/2SB |

| Power | 220V/380V |

| Vacuum pump power | 750W |

| Sealing power | 800W |

| Sealing strip | 2 |

| Vacuum chamber size | 440x490x70mm |

| Sealing size | 400x12mm |

| Weight | 180kg |

Why Choose Our Garlic Peeling Line?

- We can customize an exclusive garlic peeling line for customers.

- The cloving and peeling rate of garlic processing machinery is up to 98%.

- The garlic peeling production line will not damage the garlic during the peeling process.

- A variety of packaging methods are available.

- The garlic processing machine is widely used in food processing plants, fruit and vegetable processing plants, food wholesale markets, and many other places.

Garlic peeling production line successfully exported to Saudi Arabia

With the growing demand for garlic, a small food processing plant belonging to a Saudi Arabian customer introduced our garlic peeling line.

Before shipment, we held an online video meeting with the customer for equipment debugging and operation training. Our technicians actively answer customers’ questions to ensure that customers are familiar with the performance of the equipment, operating methods, logistics and transport, and other aspects of understanding.

After the equipment arrives in Saudi Arabia for normal operation, we also keep a regular tracking service. Timely solve the problems encountered by customers in the process of use, and carry out the necessary maintenance and maintenance recommendations.

This range of high-quality services ensures the efficient operation of the customer’s equipment and the smooth running of production.

Taizy’s Service

As a professional food machinery manufacturer, we not only provide comprehensive pre-sales service but also provide strong after-sales service.

First of all, we have a professional technical team to provide remote technical support and on-site service.

In addition, we provide training courses on the operation and maintenance of garlic processing equipment. This can help operators familiarize themselves with the use and maintenance of the garlic peeling production line.

We also keep a sufficient stock of spare parts to ensure that customers can get the required parts in time.

Contact Us!

If you need to know more about our garlic peeling production line models, customer cases, or export supporting services, please feel free to contact us for technical information and quotation suggestions!