La machine d'impression d'œufs peut imprimer rapidement et clairement des informations importantes telles que la date de production et le numéro de lot sur la surface des œufs pour garantir la traçabilité et la sécurité de chaque œuf. La machine d’impression d’œufs de Taizy peut traiter 18 000 œufs par heure. Non seulement l'efficacité du codage est élevée, mais également une variété de paramètres réglables pour s'adapter à l'utilisation de diverses industries.

Les caractéristiques du marqueur d'œufs

- Haute efficacité de codage. Taizy dispose d'une machine de codage d'œufs à six têtes d'impression avec une capacité d'impression allant jusqu'à 18,000 pièces/h, qui peut imprimer jusqu'à 430,000 morceaux par jour.

- Impression automatique haute définition. Le contenu pulvérisé par l'imprimante à jet d'encre est clair et standard, la coloration est plus solide, il n'y aura pas de flou et la couleur tombera dès qu'elle sera essuyée.

- Plusieurs polices à choisir. L'imprimante à jet d'encre peut imprimer des chiffres, des lettres chinoises et anglaises, des symboles spéciaux et des graphiques de logo, des codes à barres, des codes bidimensionnels, etc.

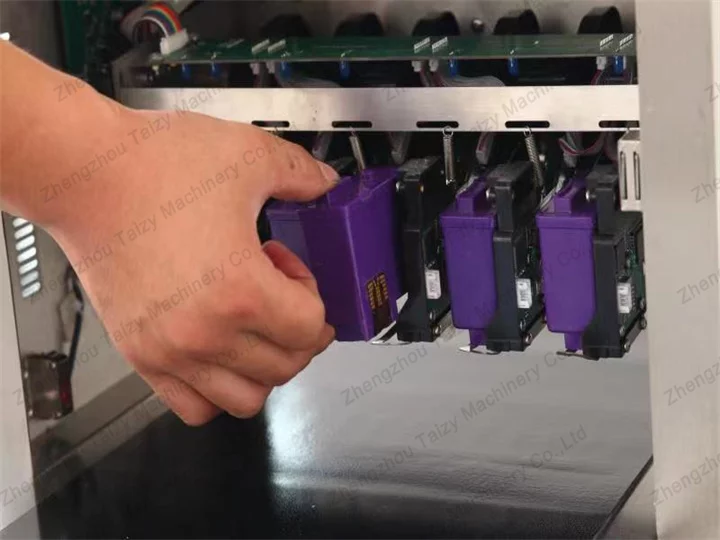

- Cartouche d'encre facile à retirer. Les cartouches adoptées utilisent des têtes d'impression de haute qualité, une photoélectricité alignée au laser, faciles à installer.

- Économisez considérablement du travail. Au lieu du fonctionnement manuel traditionnel de la machine à coder, l'imprimante à jet d'encre n'a pas besoin d'être protégée manuellement, elle termine automatiquement le processus de codage, économisant ainsi du travail, du temps et des coûts.

- Fonction de nettoyage automatique. Le nettoyage en veille a une fonction de nettoyage automatique, empêchant la cartouche de se boucher et améliorant la stabilité d'utilisation.

- Grande adaptabilité. Machine compacte et légère, facile à installer, opération simple, peut être utilisée avec n'importe quelle chaîne de montage industrielle.

Dans quels domaines pouvons-nous utiliser des machines à coder les œufs ?

- Fermes avicoles. Pour marquer les œufs frais dans la chaîne de production afin de garantir l'exactitude des informations sur le produit.

- Usines de transformation des œufs. Pour marquer les œufs pendant la transformation pour la traçabilité du produit et le contrôle qualité.

- Supermarchés et détaillants. Pour marquer les œufs au point de vente afin de renforcer la confiance des consommateurs.

- Industrie de la restauration. Pour l'étiquetage des ovoproduits faits maison afin de garantir la transparence des informations sur la sécurité alimentaire.

- Exportations alimentaires. Répondre aux normes internationales et assurer la traçabilité et la conformité des produits exportés.

Les machines à imprimer les œufs sont plus largement utilisées. Si vous n'êtes pas sûr que cette machine de marquage des œufs corresponde au scénario que vous appliquez, n'hésitez pas à nous contacter. Nous vous donnerons des réponses et des suggestions précises.

Composition partielle de la machine d'impression d'œufs

- Tête d'impression: le composant principal pour l'impression des informations, adoptant une haute précision jet d'encre technologie.

- Système d'alimentation en encre: responsable de la livraison de l'encre à la tête d'impression pour assurer la stabilité du processus d'impression.

- Panneau de contrôle: fonctions de fonctionnement et de surveillance intégrées, pratiques pour les utilisateurs pour définir les paramètres et vérifier l'état de fonctionnement.

- Tapis roulant: utilisé pour transporter les œufs vers la position d'impression afin de garantir l'efficacité de l'impression.

- Cadre: la structure globale est solide, assurant la stabilité et la durabilité de la machine.

- Système de nettoyage: la machine est équipée d'une fonction de nettoyage automatique pour garantir que les têtes d'impression ne sont pas obstruées et prolonger la durée de vie.

Comment utiliser la machine d’impression automatique d’œufs ?

Préparation

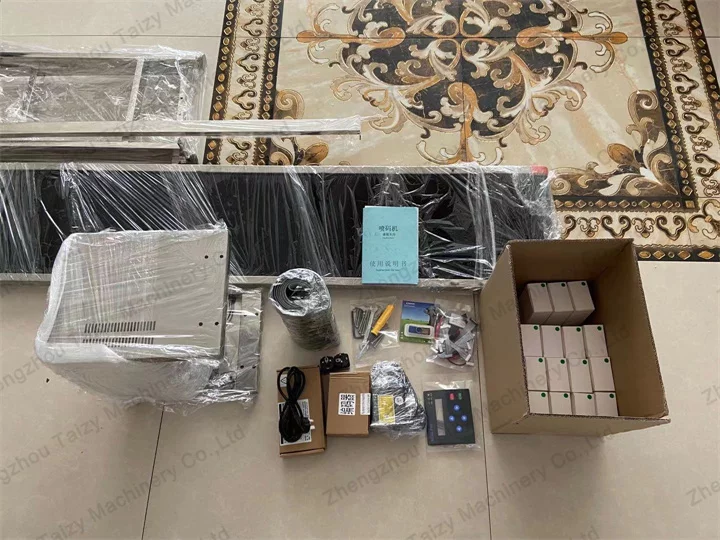

Assurez-vous que la machine à marquer les œufs est connectée à l'alimentation électrique et suivez les instructions d'installation et de débogage.

Paramètres de réglage

Définissez le contenu de l'impression sur le panneau de commande, y compris la date et le numéro de lot.

Ajuster la tête d'impression

Selon la taille et la forme des œufs, ajustez la hauteur de la buse et la distance d'impression.

Démarrer la machine

Démarrez le tapis roulant, les œufs entreront automatiquement dans la zone d'impression et la tête d'impression commencera à fonctionner.

Vérification de l'effet d'impression

Une fois l'impression terminée, vérifiez si le message sur les œufs imprimés est clair et précis.

Nettoyage régulier

Nettoyez régulièrement les têtes d'impression avec le système de nettoyage pour garantir les résultats d'impression.

Machine de marquage des œufs à vendre

| Taper | machine d'impression d'oeufs à six têtes d'impression |

| Nombre de lignes d'impression | 1 à 4 lignes |

| Hauteur du mot imprimé | 2-9mm |

| Puissance globale | <30w |

| Poids total | 15 kg |

| Tension | 110 V-250 V 50 Hz |

| Capacité | 300 pièces/min (18 000 pièces/h) |

En plus de ce modèle d'imprimante à œufs, nous avons d'autres modèles à vendre. Contactez-nous pour des devis à jour et une personnalisation !

Autres équipements liés aux œufs

Outre la machine de codage d'œufs, Taizy, en tant qu'usine professionnelle de machines alimentaires, vend également des machines à laver les œufs, des machines à trier les œufs, des machines à écaler les œufs, etc.

Si vous souhaitez une ligne complète de manipulation et de transformation des œufs, nous pouvons personnaliser la solution pour vous et configurer un équipement de haute qualité pour contribuer à améliorer l'efficacité et la qualité de la manipulation des œufs.

Méthodes de réparation et d’entretien de la machine d’impression d’œufs

- Nettoyage régulier. Nettoyez régulièrement les têtes d'impression, le système d'alimentation en encre et la bande transporteuse pour éviter que l'encre ne sèche et ne se bouche.

- Inspection des têtes d'impression. Vérifiez régulièrement l'état des têtes d'impression pour vous assurer qu'elles ne sont ni endommagées ni usées, et remplacez-les si nécessaire.

- Remplacement de l'encre. Remplacez régulièrement l'encre en fonction de la fréquence d'utilisation, évitez d'utiliser de l'encre périmée ou de qualité inférieure.

- Serrer les vis. Vérifiez régulièrement la fixation des pièces de la machine pour vous assurer qu'il n'y a pas de desserrage et pour maintenir la stabilité de la machine.

- Opération d'enregistrement. Enregistrez régulièrement l'état de fonctionnement et les défauts de la machine, afin de faciliter la détection rapide des problèmes et de les résoudre.

- Entretien professionnel. Si vous rencontrez une panne importante, vous devez contacter un personnel de maintenance professionnel pour une révision à temps afin d'éviter de démonter la machine par vous-même, ce qui entraînerait des pertes plus importantes.