Nous avons réussi à exporter un ensemble complet de ligne de lavage à bulles pour citrouilles à une entreprise de transformation de légumes au Kenya, comprenant un laveur à bulles d'une capacité de 500 kg/h, un trancheur de citrouilles, un coupe-légumes à tête unique et un séchoir.

Le client est principalement engagé dans le traitement primaire de la citrouille et dans les services de distribution de supermarché local et de restauration. Après la mise en service de la ligne de production, cela a efficacement résolu le problème de la faible efficacité du nettoyage et de la découpe manuels. Cela améliore la vitesse de production et les normes d'hygiène des produits, et jette les bases pour que l'entreprise puisse élargir son marché et renforcer sa puissance de marque.

Contexte du client : ressources agricoles riches, l'efficacité du traitement doit être améliorée

Le Kenya est situé en Afrique de l'Est, riche en ressources agricoles. La culture de la citrouille est répandue, notamment dans les comtés agricoles tels que Kajiado et la région de Kiambu, et bénéficie d'une production stable de citrouilles.

Le client est une petite et moyenne usine de transformation agro-alimentaire située en périphérie de Nairobi, qui se consacre principalement au lavage, à la découpe et à la distribution de citrouilles locales, servant de grands marchés de fruits et légumes ainsi que des chaînes de supermarchés. En raison de la grande taille de la matière première (diamètre moyen de 225 mm, circonférence d'environ 699 mm) et de la dépendance à long terme à un traitement manuel, peu efficace et intensif en main-d'œuvre, le client a un besoin urgent d'une solution de traitement automatisée pour moderniser la ligne de production.

Ligne de lavage à bulles d'air Taizy à vendre : supporte la personnalisation, s'adapte au traitement de gros fruits et légumes

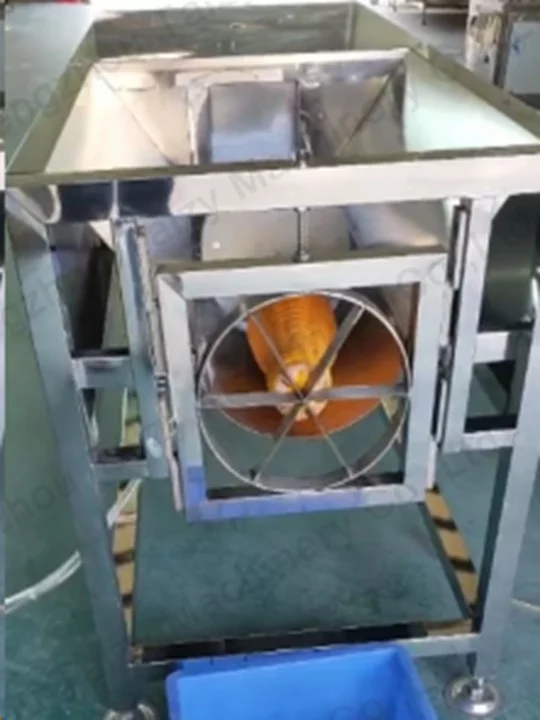

Visant les caractéristiques de la citrouille de grande taille, à peau boueuse et nécessitant un nettoyage élevé, nous fournissons une machine de lavage à bulles d'air de 500 kg/h avec les avantages suivants :

La longueur de la machine est de 3 mètres et la largeur de la bande en maille est de 800 mm, ce qui est adapté pour transporter et laver des fruits et légumes de grand diamètre.

Le tumbling à bulles haute pression et un nombre de têtes de douche personnalisable peuvent efficacement rincer la saleté de surface.

Support de personnalisation de la tension : cette machine adopte une électricité triphasée de 415V 50Hz, conforme aux normes électriques industrielles kenyanes.

Correspondant au système d'eau circulante, économie d'eau et protection de l'environnement.

La machine entière est en acier inoxydable, résistante à la corrosion, conforme aux normes d'hygiène alimentaire.

Facile à utiliser, entretien quotidien pratique, adapté à une opération par lots à long terme.

Notre solution globale pour eux : une ligne de traitement de citrouilles clé en main

Basé sur le processus de traitement de la citrouille du client, nous avons personnalisé la solution complète suivante pour eux :

Machine de lavage à bulles : convient pour le nettoyage préliminaire de la citrouille, l'élimination des sédiments de surface.

Machine de découpe : coupe la grosse citrouille entière en quartiers, pratique pour la découpe ultérieure.

Coupe-légumes à tête unique : configuration de couteaux multifonctionnelle, peut couper la citrouille en fils/tranches de 3 mm, dés de 6 mm, fonctionnement simple, changement de couteaux facile.

Séchoir à circulation d'air chaud : conçu en fonction de la teneur en eau de la citrouille, structure à plusieurs plateaux, méthode de séchage par pénétration d'air chaud, température réglable, pour assurer un séchage uniforme des tranches de citrouille, une couleur naturelle, conserver les nutriments, pratique pour la conservation à long terme et les ventes à l'exportation.

Avantages de notre service : livraison visuelle, emballage sécurisé pour protéger le transport à l'exportation

Afin de garantir que l'équipement livré répond aux attentes du client, nous effectuons des essais matériels réels pour chaque machine avant la livraison. Nous allons filmer tout le processus pour montrer l'effet du lavage, de la découpe et du séchage des citrouilles. Les clients peuvent effectuer une inspection vidéo à distance, confirmer les détails de l'équipement. Tous les emballages d'équipement sont utilisés :

La couche extérieure est laminée avec un traitement anti-humidité, s'adaptant à l'environnement de transport chaud et humide le long de la côte africaine.

Doublure en mousse épaisse pour protéger les parties clés.

La machine entière est encapsulée dans un caisson en bois renforcé pour répondre aux normes de sécurité maritime internationales.

En même temps, fournir des photos d'emballage et un service d'inspection par appel vidéo en temps réel, tout le processus de visualisation offre plus de tranquillité d'esprit.

Retour d'expérience client : fonctionnement fluide, propre et efficace, capacité de production doublée

Après l'arrivée de l'équipement au Kenya, notre entreprise a organisé des ingénieurs pour guider le client à travers l'installation vidéo à distance, le débogage et la formation à l'exploitation. Le retour du client est que tout le processus d'installation s'est déroulé sans accroc et que l'équipement fonctionne de manière stable. En particulier, l'efficacité de nettoyage a été considérablement améliorée, la précision de coupe est élevée et l'intensité de travail a été significativement réduite. Le besoin initial d'une douzaine de travailleurs par jour pour traiter la quantité de citrouilles est désormais réduit à seulement 2-3 personnes, améliorant ainsi considérablement l'efficacité et les normes d'hygiène.

Actuellement, le client prévoit de copier le modèle sur le deuxième site de traitement et a exprimé une forte volonté de coopérer avec notre entreprise sur le long terme.