A carrot packing machine greatly improves packaging efficiency and saves labor cost due to its efficient automated packaging process. It can be widely used in a variety of industries such as food, daily chemicals, pharmaceuticals or electronics. Taizy’s carrot packing machine support customers in selecting the appropriate handling capacity, motor type, number of cutters, feeding method, and other elements according to their needs. If you are looking for efficient and stable equipment, welcome to contact us!

What Types of Pillow Packaging Machine Can Pack?

Horizontal flow packing machine is not only able to pack all kinds of fresh vegetables, cut vegetables, dried vegetables and so on. It is also widely used to pack other kinds of products, such as:

- Food products: cookies, candies, nuts, bread, potato chips, frozen products, etc.

- Daily chemical products: laundry detergent, fertilizer, toilet paper, soap, cosmetics, etc.

- Electronic accessories: small batteries, electronic components, plugs, headphones, etc.

- Pharmaceutical products: medicines, health products, disinfectant wipes, etc.

- Toys and small goods: small stationery, toys, souvenirs, etc.

If you want to make sure whether your raw materials can be packed by this carrot packing machine, you can contact us immediately for consultation. We will give you a rational opinion!

Structure Composition of Carrot Packing Machine

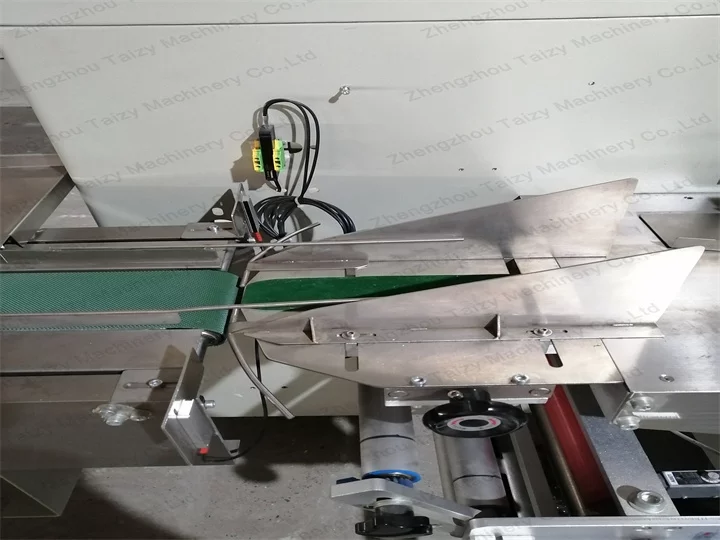

The main structural components of the vegetable packaging machine include feeding system, molding part, filling system, sealing system, cutting system, control system, conveying system and so on.

Automated Packaging Flow

- Feeding: the carrots are uniformly conveyed to the inlet of the packaging machine through the feeding system.

- Forming: the packaging film passes through the forming device to form the bag shape and is cut into appropriate size bags according to the set bag length.

- Filling: the carrots enter into the formed bag through the filling system, and the filling amount is precisely controlled according to the need.

- Sealing: under the action of the sealing system, the mouth of the bag is heat-sealed to ensure that the bag is sealed tightly.

- Cutting: the sealed bags are precisely cut by the cutting knife and separated into individual packages.

- Output: the packed bags are transferred to the next process via conveyor belt or directly into the packing box.

Why Choose an Automatic Pillow Packaging Machine?

High automation. The packing speed of carrot packing machine is 5-200 bags/min, which not only improves the working efficiency of the production line, but also greatly reduces the waste of labor and time.

Powerful utility. Since air pillow packaging machine can pack all products with regular shape, the applicability is very strong.

Intelligent control panel. Adopting large-size PLC touch screen, it can adjust the speed, temperature, bag length and other key parameters without stopping, and conveniently control the packing process.

High precision sealing. Independent PID temperature control heating bilateral turntable sealing, sealing the back of the packaged products to ensure the sealing.

Suitable for a variety of roll film materials. Multi-axis linkage film rolling coordinates film pulling, and the machine is convenient to replace multiple roll film materials.

Food Packaging Machines for Sale

| Model | TZ-250 | TZ-350 | TZ-450 | TZ-600 |

| Packaging speed(bags/min) | 5-200 | 5-200 | 5-200 | 5-200 |

| Bag length(mm) | 100-600 | 100-600 | 100-600 | 120-600 |

| Bag width(mm) | 50-110 | 50-110 | 50-110 | 50-110 |

| Bag height(mm) | ≤40 | ≤70 | ≤100 | ≤100 |

| Power | 220V, 50/60Hz, 2.4KVA | 220V, 50/60Hz, 2.4KVA | 220V, 50/60Hz, 2.6KVA | 220V, 50/60Hz, 3.4KVA |

| Machine size(mm) | 4020*720*1450 | 4020*720*1450 | 4020*720*1450 | 4380*970*1500 |

| Weight(kg) | 800 | 800 | 900 | 960 |

The technical parameters of the above 4 models can be used as a reference. If you want to order pillow packaging machines, we can customize the machine and carrot processing line according to customer needs.

Food Packaging Machine Price

The price of a pillow packaging machine is affected by a variety of factors, including the specifications of the equipment, brand, function, production efficiency, customization requirements, selected materials and so on. Below contents are the approximate price range of pillow packaging machines:

- Low-end pillow packaging machine: approximately $3,000 to $10,000 for simple packaging needs.

- Mid-range carrot packing machine: approximately $10,000 to $30,000, suitable for small to medium scale production.

- High-end food packaging machine: approximately $30,000 to $100,000 for large-scale production and special customization needs.

These prices are just a general range. The exact price needs to be further confirmed based on suppliers, market changes, customization needs and other factors. If you have specific needs, we recommend contacting the food packaging machine supplier for a detailed quote and equipment specifications.

Taizy Food Machinery: a Pillow Packaging Machine Manufacturer

- Technology leadership. Our company has advanced R & D technology, selling a variety of types of packaging machines. 13 years of packaging machines innovation and upgrading, to ensure that the performance of the machines are always in the industry’s leading level.

- Customized solutions. We will provide customized food packaging machine solutions according to customers’ needs to help customers improve production efficiency and reduce costs.

- Strict quality control. All pillow packaging machines pass strict quality inspection to ensure that each machine meets the industry standard and provides stable packaging performance.

- Attentive after-sales service. We provide one-year warranty period, commissioning, operation training, maintenance and other service content to ensure that customers quickly into production.

Frequently Asked Questions

What Are the Packaging Methods of Pillow Packaging Machine?

The air pillow packaging machine currently only supports back sealing as a method.

Is Carrot Packing Machine Suitable for Small Batch Production?

Although pillow packaging machines are most efficient in mass production, they can also be adapted to the needs of small batch production. Adjusting the parameters of the machine can realize the packaging tasks of different production scales.

What Types of Packaging Films Are Food Packaging Machines Suitable for?

The automatic flow packing machine is widely applicable to many types of packaging films, including PE, PP, aluminum foil, paper-plastic composite film, etc., which is suitable for different types of product packaging needs.