How to efficiently and non-destructively clean the skin of soft, easily damaged fruits and vegetables is a major problem plaguing many food factories and central kitchens. Artificial cleaning efficiency is low, difficult to perform batch operations. Ordinary water rinsing equipment can easily damage the skin of fruits and vegetables in the cleaning process, affecting product quality and sales value.

In the face of this pain point, the air bubble cleaner machine came into being, becoming the new choice of many fruit and vegetable processing enterprises.

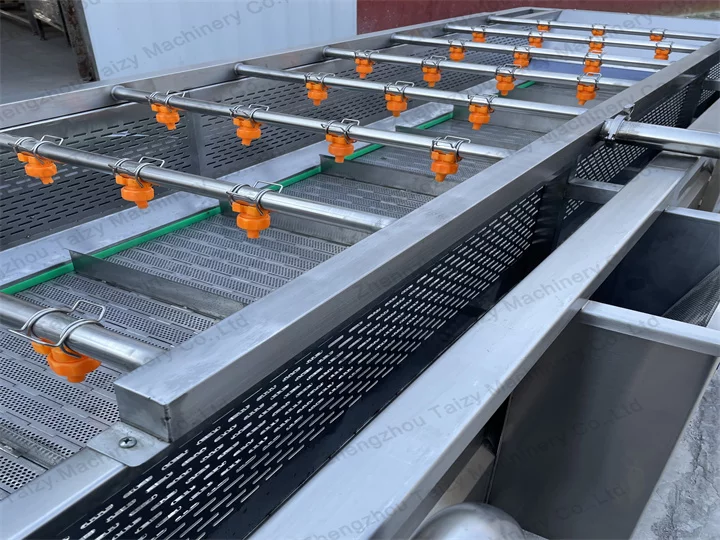

This equipment imitates the “artificial scrubbing” principle. And it combines bubble tumbling, water flow to promote and multi-level spray, greatly improving the cleaning efficiency and fruit and vegetable intact rate. It is one of the most gentle and efficient ways to deal with fragile fruits and vegetables.

Why choose an air bubble cleaner?

Flexible bubble tumbling, no injury to the skin

The bottom of the device releases a large number of air bubbles, which drive the fruits and vegetables to move gently through the tumbling of the body of water. This avoids mechanical collision and protects the integrity of the skin.

Sediment impurities are easily removed

The triple combination of water flow, bubbles, and spray effectively removes adhering sediment, pesticide residue, bacteria, and more.

Convenient cleaning, food-grade hygiene standard

The whole machine is made of 304 stainless steel, in line with food processing safety standards. Easy cleaning and maintenance, strong corrosion resistance.

Suitable for a wide range of fruit and vegetable types

Suitable for blueberries, strawberries, tomatoes, peaches, grapes, asparagus, carrots, and other fruit and vegetable ingredients of different hardness.

Can be linked with lifting, air drying, picking, and other equipment

Meets the needs of washing line automation and supports customized production line layouts.

Wide range of applications

Bubble washers are not only suitable for fruit and vegetable processing plants and central kitchens, but also for export-oriented agricultural enterprises and freshness distribution centers.

It is especially suitable for the pre-treatment of export-grade fruits and vegetables, which significantly reduces the loss rate and enhances the added value of commodities.

Conclusion

With the continuous improvement of consumer demand for fruit and vegetable quality, traditional cleaning methods have been difficult to meet the flexible, efficient, and safe cleaning needs. Air bubble cleaner, as an important part of the modern fruit and vegetable processing technology, is gradually becoming a new trend in the industry.

Now is a good time to invest in upgrading the cleaning link!

View product details and technical parameters: