Garlic, an indispensable seasoning in global cuisine, enjoys enduring market demand. However, the high post-harvest loss rate of 20%-30% for fresh garlic and the cumbersome manual processing severely limit its industrial value.

This is precisely where garlic powder—a processed product with an 18-month shelf life, convenient usage, and wide applications—demonstrates its immense commercial value. So the core question arises: Is investing in a fully automated garlic powder production line truly profitable?

Potential for over 300% value enhancement

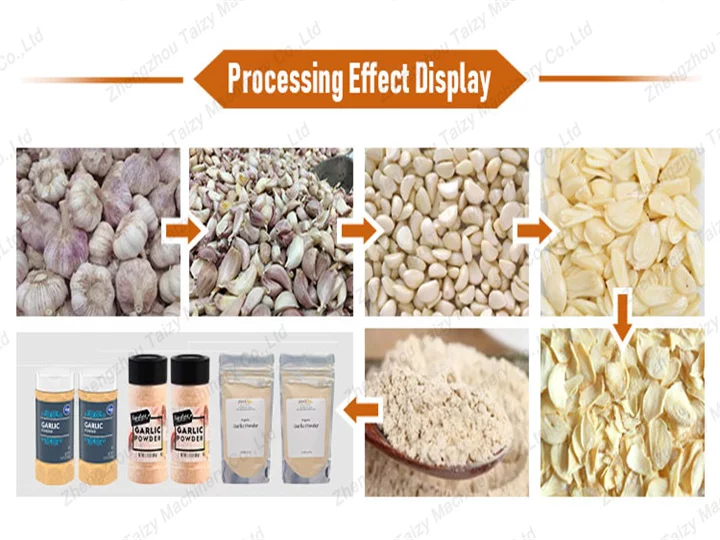

The core of the garlic powder business lies in “value enhancement.” Using market averages as an example, typically 4-5 kilograms of fresh garlic can produce 1 kilogram of high-quality garlic powder.

Assumption:

Fresh garlic purchase price: $0.5/kg

Garlic powder market price: $8.0/kg

Cost calculation:

Raw material cost for producing 1 kg of garlic powder is approximately 5 kg * $0.5/kg = $2.5.

Value comparison: $8.0 (selling price) vs $2.5 (raw material cost) – product value increases by over 320%!

Extend the sales cycle: by extending the shelf life from 1-2 months to over 18 months, seasonal limitations are overcome, enabling year-round sales.

Expand market channels: garlic powder serves as a key ingredient for numerous industries, including seasoning companies, meat processing plants, and snack food manufacturers. Its market scale far exceeds that of traditional fresh produce markets.

How can automated production lines turn potential into tangible returns?

To achieve the aforementioned value enhancement, efficient and low-cost automated production is key. A complete garlic powder production line maximizes profit potential through the following core equipment:

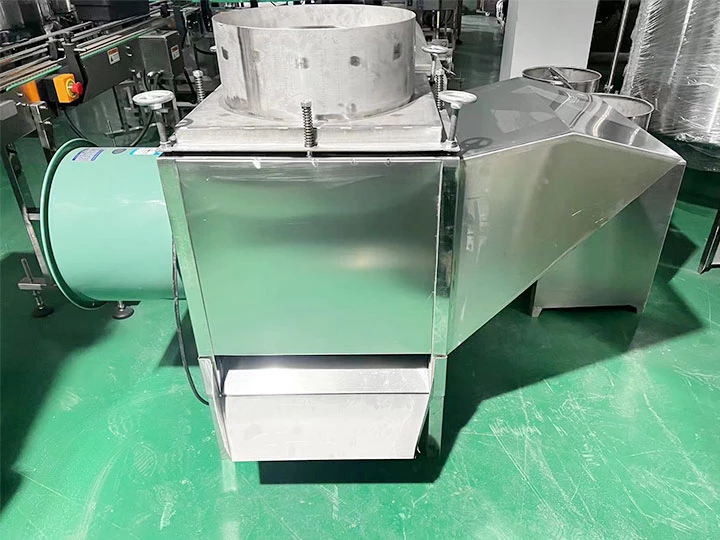

Garlic Separating Machine

Function: efficiently separates whole garlic bulbs into individual cloves.

A 500-kilogram-per-hour clove separator matches the output of 10 to 15 skilled workers, directly and significantly reducing your labor costs.

Garlic Peeling Machine

Function: utilizes airflow technology to gently and rapidly remove the outer skin of garlic cloves.

Significantly reduces labor requirements once again. Simultaneously, a peeling rate of up to 98% and a damage rate below 2% ensure maximum utilization of raw materials.

This translates to less than 2 kilograms of waste per 100 kilograms of raw material, meaning every precious gram of raw material is converted into profit.

Continuous Drying Machine

Function: precisely controls temperature between 60-75°C to reduce moisture content in garlic slices from 80% to below 6%.

This is the key to “value preservation” for the product. An efficient drying system means lower energy consumption and higher output. Unlike traditional sun-drying, it operates independently of weather conditions.

Garlic Grinding Machine

Function: rinds dried garlic slices into a fine powder with a particle size of 80-120 mesh.

By replacing the screen mesh with different mesh sizes according to customer requirements, you can produce garlic powder of varying specifications (coarseness) to meet the differentiated demands of different markets.

Finely processed products typically command a price premium of over 15% compared to coarsely processed products, maximizing profits.

Four pillars of profitability for garlic powder production lines

In summary, the profitability of investing in a garlic powder production line rests upon four solid pillars:

Robust market demand: the global seasoning market grows steadily at 5% annually.

Significant value enhancement: over 300% value growth potential from raw materials to finished products.

Extremely low operating costs: high automation reduces labor—the largest variable cost—by over 80%.

Maximized raw material utilization: even visually imperfect garlic can be processed into high-quality garlic powder, achieving over 95% raw material utilization.

Conclusion

So, returning to our original question: is a garlic powder production line profitable? The data provides a clear answer. It is not a one-time equipment purchase, but a high-return business venture capable of generating long-term, stable cash flow.

Ready to transform local garlic resources into the golden powder in high demand across global markets? Contact our product specialists today for a complimentary customized proposal featuring detailed equipment configurations!