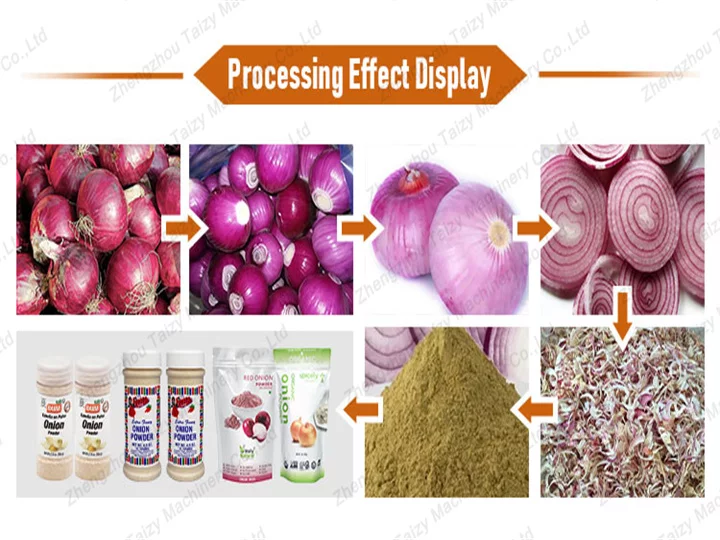

In the food processing industry, onion powder is gaining popularity in the market due to its strong flavor and convenient use. To realize large-scale and high-quality production of onion powder, a complete and efficient onion powder production line is crucial.

What machines are used in an onion powder processing plant?

Onion powder production line equipment

Onion root cutter

The root cutting machine is used to remove the root of onions quickly, with high efficiency and low loss, suitable for batch primary processing treatment. Its high degree of automation effectively reduces manual operation and improves work efficiency.

Functional features:

- Automatically cuts onion roots and tops to ensure precise cutting.

- Highly efficient processing capacity, can handle thousands of onions per hour.

- No damage to the main body of the onion, reducing the waste of raw materials.

Onion peeling machine

The equipment utilizes pneumatic principles to realize rapid peeling of onions without hurting the onion flesh, and the rate of peeling clean is up to 95% or more. It is an indispensable preliminary processing equipment for modern onion powder production.

Functional features:

- Automatic peeling reduces manual labor.

- Clean and thorough peeling, no need for extra cleaning.

- Highly efficient processing speed, suitable for mass production.

Brush cleaning machine

Peeled onions are deep-cleaned by brush rollers to effectively remove residual impurities and floating skins, ensuring cleanliness and safety in subsequent processes.

Functional features:

- Flexible brush cleaning, no damage to the onion surface.

- Equipped with a water circulation system, which saves water.

- Adjustable cleaning intensity adapts to different onion varieties.

Onion cutting machine

The cutting machine can evenly cut onions into thin slices, strips, or granules for the subsequent drying process. The cutting thickness is adjustable to meet different product specifications.

Functional features:

- Uniform cutting to ensure a consistent drying effect.

- Adjustable cutting size to adapt to different processing requirements.

- High-speed cutting improves production efficiency.

Onion drying oven

The drying box adopts a multi-layer mesh belt structure and a hot air circulation principle to realize even dehydration of onion slices and retain the original flavor and nutrition. This equipment has the advantages of energy saving, environmental protection, and easy operation.

Functional features:

- Hot air circulation system, energy saving, and high efficiency.

- Adjustable temperature, adapts to different drying needs.

- Large capacity design, to meet the large-scale production.

Onion milling machine

Dehydrated onion slices are converted into fine powder after being processed by the milling machine. The equipment supports multi-stage grinding, and the output onion powder has uniform particles and controllable fineness, which is one of the core equipment to ensure the quality of the product.

Functional characteristics:

- High-speed grinding, fine and uniform powder.

- Equipped with a dust removal system to keep the production environment clean.

- Easy to operate and maintain, reducing operational costs.

Onion powder packaging machine

In the last step, the packaging machine automatically measures, fills, and seals the onion powder. This ensures a hygienic product with a long shelf life, while improving packaging efficiency and aesthetics.

Functional features:

- Automatic quantitative packaging to ensure the consistent weight of each bag.

- Support multiple packaging forms.

- High-speed packaging improves production efficiency.

Advantages of the onion powder production line

- Fully automated production: the whole process from root cutting to packing is automated, reducing manual operation and improving production efficiency.

- High-quality output: each machine adopts advanced technology to ensure the quality and uniformity of onion powder.

- Energy saving and environmental protection: the design of the equipment emphasizes energy saving, water circulation system, and hot air circulation technology to reduce energy consumption.

- Easy maintenance: modularized design facilitates maintenance and cleaning, and reduces downtime.

- Flexible configuration: the production line equipment can be adjusted according to the demand, adapting to different production capacities and product specifications.

Conclusion

An efficient onion powder production line not only improves product quality but also significantly reduces labor and energy costs. If you’re looking for the right onion powder processing solution for your business, this complete equipment package is certainly an option worth considering.

For more details, feel free to visit our production line page: