Fully automatic packaging machine can easily realize automatic powder packaging such as bag making, measuring, filling, sealing, slitting and counting, and finally get the ginger powder bag with uniform weight and quality. It is widely used in food, chemical, pharmaceutical and other industries for its high efficiency and high precision.

Applications of Fully Automatic Packaging Machine

The powder packaging equipment is adapted to the automatic metering and packaging of various powders, such as milk powder, coffee, soy milk powder, sesame paste, lotus root powder, coloring powder, seasoning powder, medicinal powder and so on.

If you are not sure whether your raw material is suitable for the automation packaging machine, you can contact us for consultation.

Automatic Powder Packaging Machine Advantages

- High efficiency. The food powder packaging machine can complete the large quantity of packaging ginger powder in a short time, effectively reducing the labor cost and time cost, and improving the production efficiency.

- 304 stainless steel material. The fully automatic packaging machine is made of 304 stainless steel material and adopts a closed packaging process, ensuring sanitary safety.

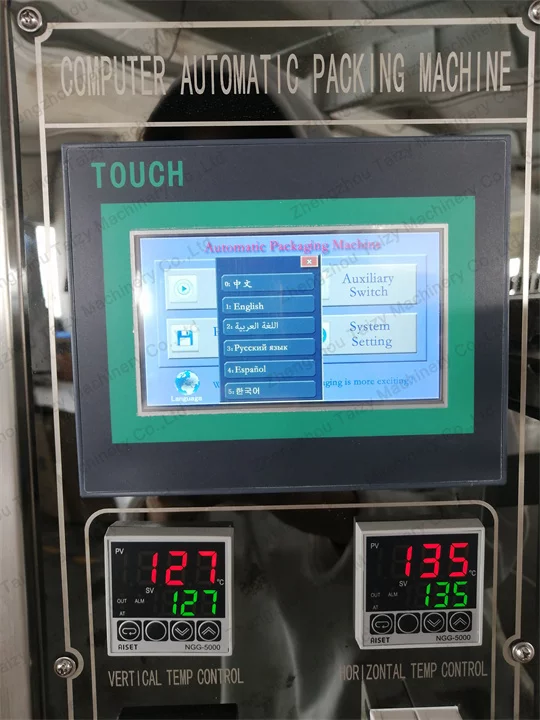

- Easy to operate and maintain. It adopts double CPU microcomputer control system, large screen LCD display, simple and easy to use operation interface.

- Automatic measuring and packaging. It is equipped with high-precision weighing and metering system, which can ensure the consistency of weight of each bag.

- Precise slitting. The high precision stepper motor ensures the accuracy of the slitting position of each bag.

- Customization. Optionally, it can be equipped with coding machine, continuous bag, easy-tear notch, downward flinging knife, rounding corner punching, exhausting or inflating device.

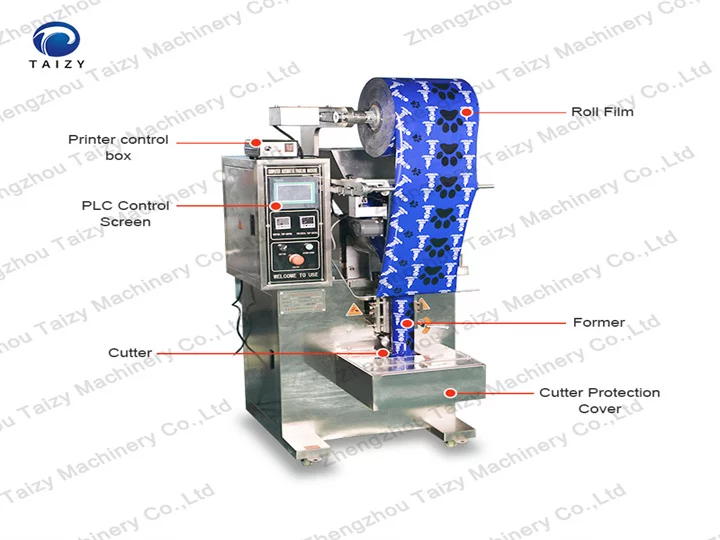

Food Powder Packaging Machine Structure

The structure of automatic powder packaging machine mainly includes hopper, screw conveyor system, measuring device, molding device, heat sealing system, cutting device, control system and other parts.

How to Package Powder Products?

Material Conveying

The screw conveys the powder from the hopper to the doser. The screw is rotated to ensure an even flow of material.

Dosing and Weighing

The built-in load cell of the machine monitors the weight of the material in real time to ensure accurate metering.

Packaging Molding

Packaging film is heated and stretched to form bags. After weighing, the material is quickly put into the formed bag through the discharge opening.

Sealing

After the packaging is completed, the fully automatic packaging machine closes the mouth of the bag through the heat sealing system to ensure the sealing of the packaging.

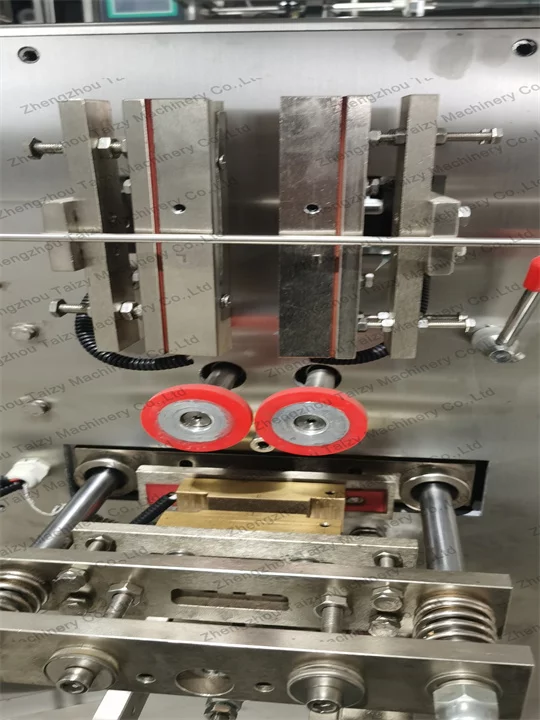

Cutting

Finally, the cutting knife cuts the bag to complete the whole packaging process.

Powder Filling Machine for Sale

Vertical form fill and seal packaging machines are classified into inclined push screw packaging machines, flat push screw packaging machines and straight push screw packaging machines according to different pushing methods.

Inclined Push Screw Powder Packaging Machine

Working principle: it mainly adopts the way of slanting screw to push down the material, pushing the powder into the bag through the slant. It is more suitable for packing powders with poor fluidity.

Selling models: TH-320, TH-450

Sealing forms: three side sealing, four side sealing or back sealing are available.

| Model | TH-320 |

| Packing speed | 24-60 bags/min |

| Bag length | 30-175 mm |

| Bag width | 25-145 mm |

| Filling range | 0.5-3 ml, 3-10 ml, 10-60 ml |

| Power consumption | 2.2 kw |

| Weight | 280 kg |

| Dimensions | 1100*750*1820 mm |

Flat Push Screw Powder Packaging Machine

Working principle: it mainly pushes horizontally through the screw to push the powder directly into the bag.

Selling models: TH-320, TH-450

Sealing forms: three side sealing, four side sealing or back sealing are available.

| Model | TH-450 |

| Packing speed | 30-75 bags/min |

| Bag length | 30-300 mm |

| Bag width | 30-215 mm |

| Filling range | 5-700 ml |

| Power consumption | 1.2 kw |

| Weight | 250 kg |

| Dimensions | 820*1250*1900 mm |

Straight Push Screw Powder Packaging Machine

Working principle: it pushes the powder directly into the bag by vertical pushing and relies on gravity to push the material forward. It is usually paired with screw conveyor machine, which is more efficient and convenient to convey the powder to the packing machine inlet.

Selling models: TH-320, TH-450

Sealing forms: three side sealing, four side sealing or back sealing are available.

| Model | TH-450 |

| Packing speed | 30-80 bags/min |

| Bag length | 30-300 mm |

| Bag width | 40-430 mm |

| Filling range | 50-1000 ml |

| Power consumption | 1.8 kw |

| Weight | 400 kg |

| Dimensions | 820*1220*2000 mm |

We have a wide range of vertical form fill and seal packaging machines for sale. For ginger production line, we have ginger dryer, ginger grinder machine, ginger cleaning machine. If you would like to know more about the parameters, customized services and so on, we can provide you with more information.

Automatic Powder Filling Machine Price

The price of a packaging powder machine is affected by a number of factors, including the degree of automation and functionality of the packaging machine, production capacity, quality of the equipment, brand awareness, customization needs, after-sales service and warranty period.

Generally speaking, among the fully automatic packaging machines, the straight push screw packaging machine is more expensive. The inclined push screw powder packaging equipment is more expensive than the flat push screw packaging powder machine.

Taizy food machinery is one of the powder packaging machine manufacturers. We have 13 years of experience in R&D and production of packaging machinery. Welcome to ask us the latest prices for the automatic auger powder filling machine.

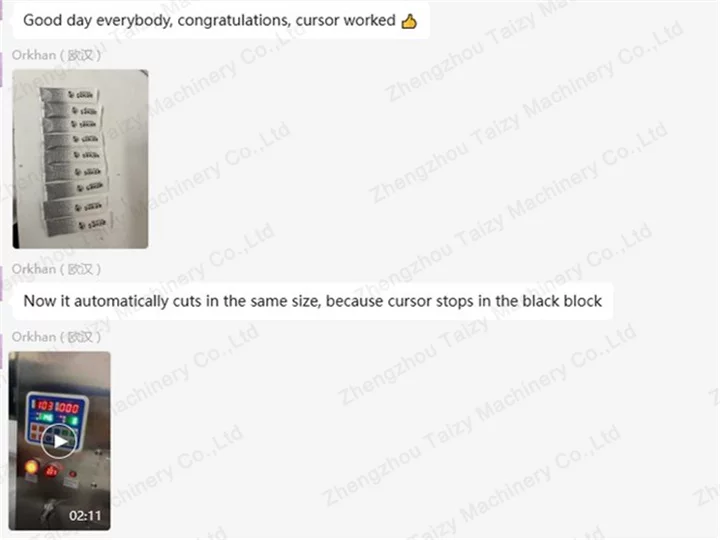

A Successful Case of Fully Automatic Packaging Line

Recently, our packaging machine customer, Orkhan, sent us a feedback video and information about the automatic auger powder filling machine. The customer expressed his approval of the stability of the fully automatic packaging machine and the quality of the product.